Page 112 - Icon Ridge Presents ATORN

P. 112

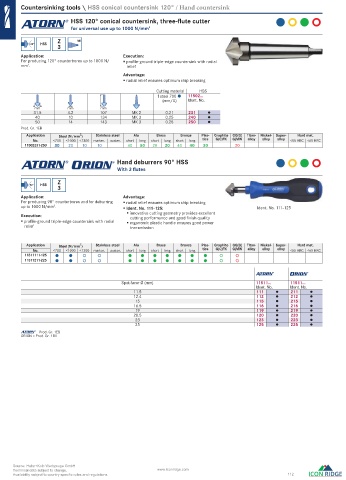

Countersinking tools \ HSS conical countersink 120° / Hand countersink

HSS 120° conical countersink, three-fl ute cutter

for universal use up to 1000 N/mm 2

Z MK

HSS

3

Application: Execution:

For producing 120° counterbores up to 1000 N/ profi le-ground triple-edge countersink with radial

mm . 2 relief

Advantage:

radial relief ensures optimum chip breaking

Cutting material HSS

f steel 700 11502...

(mm/U) Ident. No.

mm mm mm

31.5 4.2 107 MK 2 0.21 231

40 10 134 MK 3 0.25 240

50 14 143 MK 3 0.28 250

Prod. Gr. 1EB

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11502231-250 30 20 10 10 40 50 20 20 40 40 30 20

Hand deburrers 90° HSS

With 3 fl utes

Z

HSS

3

Application: Advantage:

For producing 90° counterbores and for deburring radial relief ensures optimum chip breaking

up to 1000 N/mm . 2 Ident. No. 111–125: Ident. No. 111–125

Execution: innovative cutting geometry provides excellent

cutting performance and good fi nish quality

profi le-ground triple-edge countersink with radial ergonomic plastic handle ensures good power

relief transmission

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11511111-125

11511211-225

Spot-facer Ø (mm) 11511... 11511...

Ident. No. Ident. No.

11.5 111 211

12.4 112 212

15 115 215

16.5 116 216

19 119 219

20.5 120 220

23 123 223

25 125 225

a = Prod. Gr. 1EB

ORION = Prod. Gr. 1EH

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 112

0137_EN_2018_KERN[21846821]-h.indd 138 12/17/2018 3:31:06 PM