Page 115 - Icon Ridge Presents ATORN

P. 115

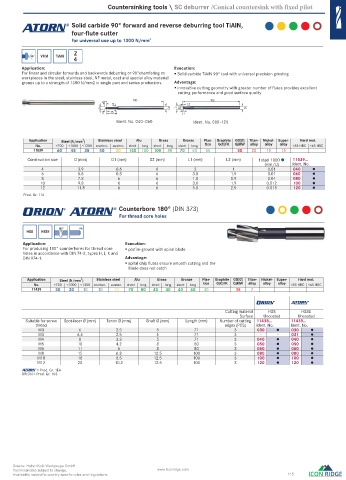

Countersinking tools \ SC deburrer /Conical countersink with fixed pilot

Solid carbide 90° forward and reverse deburring tool TiAlN,

four-fl ute cutter

for universal use up to 1300 N/mm 2

Z

VHM TiAlN

4

Application: Execution:

For linear and circular forwards and backwards deburring or 90°chamfering on Solid carbide TiAlN 90° tool with universal precision grinding

workpieces in the steel, stainless steel, NF metal, cast and special alloy material

groups up to a strength of 1300 N/mm2 in single part and series production. Advantage:

innovative cutting geometry with greater number of fl utes provides excellent

cutting performance and good surface quality

100 100

L2

4 L2

D D2 D D1 D2

15

L1 L1

Ident. No. 040–060 Ident. No. 080–120

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11539 60 45 35 40 30 140 180 100 80 70 60 55 50 20 15 15

Construction size D (mm) D1 (mm) D2 (mm) L1 (mm) L2 (mm) f steel 1000 11539...

(mm/U) Ident. No.

4 3.9 0.6 6 2 1 0.01 040

6 5.8 0.8 6 3.8 1.9 0.01 060

8 7.8 6 6 1.8 0.9 0.01 080

10 9.8 6 6 3.8 1.9 0.012 100

12 11.8 6 6 5.8 2.9 0.015 120

Prod. Gr. 114

Counterbore 180° ( DIN 373 )

For thread core holes

180° HA

HSS HSSE

Application: Execution:

For producing 180° counterbores for thread core profi le-ground with spiral blade

holes in accordance with DIN 74-2, types H, J, K and

DIN 974-1. Advantage:

spiral chip fl utes ensure smooth cutting and the

blade does not catch

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11439 30 20 10 10 10 70 80 45 40 40 40 30 15 7

Cutting material HSS HSSE

Surface Uncoated Uncoated

Suitable for screw Spot-facer Ø (mm) Tenon Ø (mm) Sha Ø (mm) Length (mm) Number of cutting 11438... 11439...

thread edges (PCS) Ident. No. Ident. No.

M3 6 2.5 5 71 3 030 030

M3 6.5 2.5 5 71 3 - - 031

M4 8 3.3 5 71 3 040 040

M5 10 4.2 8 80 3 050 050

M6 11 5 8 80 3 060 060

M8 15 6.8 12.5 100 3 080 080

M10 18 8.5 12.5 100 3 100 100

M12 20 10.2 12.5 100 3 120 120

a = Prod. Gr. 1EA

ORION = Prod. Gr. 103

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 115

0141_EN_2018_KERN[21846830]-e.indd 141 12/17/2018 3:31:02 PM