Page 22 - Icon Ridge Presents ATORN

P. 22

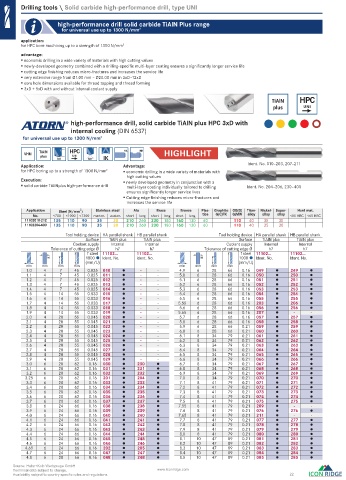

Drilling tools \ Solid carbide high-performance drill, type UNI

high-performance drill solid carbide TiAlN Plus range

for universal use up to 1300 N/mm 2

application:

for HPC bore machining up to a strength of 1300 N/mm 2

advantage:

economic drilling in a wide variety of materials with high cutting values

newly-developed geometry combined with a drilling-specifi c multi-layer coating ensures a signifi cantly longer service life

cutting edge fi nishing reduces micro-fractures and increases the service life

very extensive range from Ø1.00 mm – Ø20.00 mm in 3xD–12xD

core hole dimensions available for thread tapping and thread forming

3xD + 5xD with and without internal coolant supply

TiAlN HPC

plus UNI

high-performance drill, solid carbide TiAlN plus HPC 3xD with

internal cooling ( DIN 6537 )

for universal use up to 1300 N/mm 2

TiAlN HPC HA HB

VHM

plus UNI IK

3xD 140°

Application: Advantage: Ident. No. 010–203, 207–211

for HPC boring up to a strength of 1300 N/mm 2 economic drilling in a wide variety of materials with

high cutting values

Execution: newly developed geometry in conjunction with a

solid carbide TiAlNplus high-performance drill multi-layer coating individually tailored to drilling Ident. No. 204–206, 230–400

ensures signifi cantly longer service lives

Cutting edge fi nishing reduces micro-fractures and

increases the service life

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11102010-212 135 110 90 35 30 210 260 230 180 160 130 60 110 40 35 30

11102204-400 135 110 90 35 30 210 260 230 180 160 130 60 110 40 35 30

Tool holding device HA parallel shank HB parallel shank Tool holding device HA parallel shank HB parallel shank

Surface TiAlN plus TiAlN plus Surface TiAlN plus TiAlN plus

Coolant supply Internal Internal Coolant supply Internal Internal

Tolerance of cutting edge Ø h7 h7 Tolerance of cutting edge Ø h7 h7

f steel 11102... 11102... f steel 11102... 11102...

h6 1000 Ident. No. Ident. No. h6 1000 Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

1.0 4 7 45 0.025 010 ● - - 4.9 6 28 66 0.16 049 ● 249 ●

1.1 4 7 45 0.025 011 ● - - 5.0 6 28 66 0.16 050 ● 250 ●

1.2 4 7 45 0.025 012 ● - - 5.1 6 28 66 0.16 051 ● 251 ●

1.3 4 7 45 0.025 013 ● - - 5.2 6 28 66 0.16 052 ● 252 ●

1.4 4 7 45 0.025 014 ● - - 5.3 6 28 66 0.16 053 ● 253 ●

1.5 4 14 55 0.033 015 ● - - 5.4 6 28 66 0.16 054 ● 254 ●

1.6 4 14 55 0.033 016 ● - - 5.5 6 28 66 0.16 055 ● 255 ●

1.7 4 14 55 0.033 017 ● - - 5.55 6 28 66 0.16 203 ● 206 ●

1.8 4 14 55 0.033 018 ● - - 5.6 6 28 66 0.16 056 ● 256 ●

1.9 4 14 55 0.033 019 ● - - 5.65 6 28 66 0.16 207 ● - -

2.0 4 20 55 0.045 020 ● - - 5.7 6 28 66 0.16 057 ● 257 ●

2.1 4 20 55 0.045 021 ● - - 5.8 6 28 66 0.16 058 ● 258 ●

2.2 4 20 55 0.045 022 ● - - 5.9 6 28 66 0.21 059 ● 259 ●

2.3 4 20 55 0.045 023 ● - - 6.0 6 28 66 0.21 060 ● 260 ●

2.4 4 20 55 0.045 024 ● - - 6.1 8 34 79 0.21 061 ● 261 ●

2.5 4 20 55 0.045 025 ● - - 6.2 8 34 79 0.21 062 ● 262 ●

2.6 4 20 55 0.045 026 ● - - 6.3 8 34 79 0.21 063 ● 263 ●

2.7 4 20 55 0.045 027 ● - - 6.4 8 34 79 0.21 064 ● 264 ●

2.8 4 20 55 0.045 028 ● - - 6.5 8 34 79 0.21 065 ● 265 ●

2.9 4 20 55 0.045 029 ● - - 6.6 8 34 79 0.21 066 ● 266 ●

3.0 6 20 62 0.16 030 ● 230 ● 6.7 8 34 79 0.21 067 ● 267 ●

3.1 6 20 62 0.16 031 ● 231 ● 6.8 8 34 79 0.21 068 ● 268 ●

3.2 6 20 62 0.16 032 ● 232 ● 6.9 8 34 79 0.21 069 ● 269 ●

3.25 6 20 62 0.16 201 ● 204 ● 7.0 8 34 79 0.21 070 ● 270 ●

3.3 6 20 62 0.16 033 ● 233 ● 7.1 8 41 79 0.21 071 ● 271 ●

3.4 6 20 62 0.16 034 ● 234 ● 7.2 8 41 79 0.21 072 ● 272 ●

3.5 6 20 62 0.16 035 ● 235 ● 7.3 8 41 79 0.21 073 ● 273 ●

3.6 6 20 62 0.16 036 ● 236 ● 7.4 8 41 79 0.21 074 ● 274 ●

3.7 6 20 62 0.16 037 ● 237 ● 7.5 8 41 79 0.21 075 ● 275 ●

3.8 6 24 66 0.16 038 ● 238 ● 7.55 8 41 79 0.21 209 ● - -

3.9 6 24 66 0.16 039 ● 239 ● 7.6 8 41 79 0.21 076 ● 276 ●

4.0 6 24 66 0.16 040 ● 240 ● 7.65 8 41 79 0.21 211 ● - -

4.1 6 24 66 0.16 041 ● 241 ● 7.7 8 41 79 0.21 077 ● 277 ●

4.2 6 24 66 0.16 042 ● 242 ● 7.8 8 41 79 0.21 078 ● 278 ●

4.3 6 24 66 0.16 043 ● 243 ● 7.9 8 41 79 0.21 079 ● 279 ●

4.4 6 24 66 0.16 044 ● 244 ● 8.0 8 41 79 0.21 080 ● 280 ●

4.5 6 24 66 0.16 045 ● 245 ● 8.1 10 47 89 0.21 081 ● 281 ●

4.6 6 24 66 0.16 046 ● 246 ● 8.2 10 47 89 0.21 082 ● 282 ●

4.65 6 24 66 0.16 202 ● 205 ● 8.3 10 47 89 0.21 083 ● 283 ●

4.7 6 24 66 0.16 047 ● 247 ● 8.4 10 47 89 0.21 084 ● 284 ●

4.8 6 28 66 0.16 048 ● 248 ● 8.5 10 47 89 0.21 085 ● 285 ●

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 22

0022_EN_2018_KERN[21841676]-j.indd 22 12/17/2018 3:31:06 PM