Page 264 - Icon Ridge Presents ATORN

P. 264

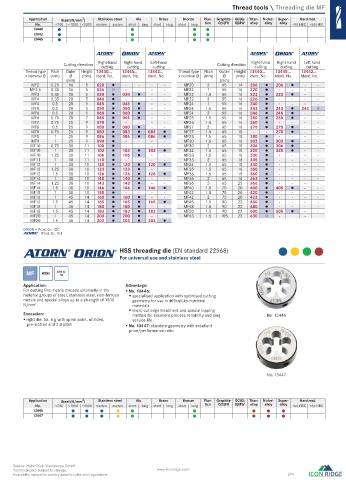

Thread tools \ Threading die MF

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13440

13442

13445

Cutting direction Right-hand Right-hand Le -hand Cutting direction Right-hand Right-hand Le -hand

cutting

cutting

cutting

cutting

cutting

cutting

Thread type Pitch Outer Height 13440... 13445... 13442... Thread type Pitch Outer Height 13440... 13445... 13442...

x nominal Ø (mm) Ø (mm) Ident. No. Ident. No. Ident. No. x nominal Ø (mm) Ø (mm) Ident. No. Ident. No. Ident. No.

(mm) (mm)

MF2 0.25 16 5 020 - - - - MF20 2 45 14 206 206 - -

MF2.6 0.35 16 5 026 ○ - - - - MF22 1 55 16 220 - - - -

MF3 0.35 20 5 030 030 - - MF22 1.5 55 16 223 223 - -

MF4 0.35 20 5 040 - - - - MF22 2 55 16 226 - - - -

MF4 0.5 20 5 045 045 - - MF24 1 55 16 240 - - - -

MF5 0.5 20 5 050 050 - - MF24 1.5 55 16 243 243 243 ○

MF6 0.5 20 5 060 060 - - MF24 2 55 16 246 246 - -

MF6 0.75 20 7 065 065 - - MF25 1.5 55 16 250 255 - -

MF7 0.75 25 9 070 - - - - MF26 1.5 55 16 260 - - - -

MF8 0.5 25 9 080 080 - - MF27 2 65 18 275 275 - -

MF8 0.75 25 9 083 083 083 MF27 1.5 65 18 - - 270 - -

MF8 1 25 9 086 086 086 MF28 1.5 65 18 280 - - - -

MF9 1 25 9 090 - - - - MF30 1.5 65 18 303 303 - -

MF10 0.75 30 11 100 - - - - MF30 2 65 18 306 306 - -

MF10 1 30 11 103 103 103 MF32 1.5 65 18 320 320 - -

MF10 1.25 30 11 106 106 - - MF33 1.5 65 18 330 - - - -

MF11 1 30 11 110 - - - - MF33 2 65 18 335 - - - -

MF12 1 38 10 120 120 120 MF34 1.5 65 18 340 - - - -

MF12 1.25 38 10 123 123 - - MF35 1.5 65 18 350 - - - -

MF12 1.5 38 10 126 126 126 MF36 1.5 65 18 360 - - - -

MF14 1 38 10 140 140 - - MF36 2 65 18 363 - - - -

MF14 1.25 38 10 143 143 - - MF36 3 65 25 366 - - - -

MF14 1.5 38 10 146 146 146 MF40 1.5 75 20 400 405 - -

MF15 1 38 10 150 - - - - MF42 1.5 75 20 420 - - - -

MF16 1 45 14 160 160 - - MF42 2 75 20 423 - - - -

MF16 1.5 45 14 165 165 165 MF45 1.5 90 22 450 - - - -

MF18 1 45 14 180 180 - - MF48 1.5 90 22 480 - - - -

MF18 1.5 45 14 183 183 183 MF50 1.5 90 22 500 505 - -

MF20 1 45 14 200 200 - - MF63 1.5 105 22 630 ○ - - - -

MF20 1.5 45 14 203 203 203

ORION = Prod. Gr. 1DC

a = Prod. Gr. 1KJ

HSS threading die ( EN standard 22568 )

For universal use and stainless steel

MF HSSE DIN 13

6g

Application: Advantage:

For cutting fi ne metric threads externally in the No. 13446:

material groups of steel, stainless steel, non-ferrous specialised application with optimised cutting

metals and special alloys up to a strength of 1300 geometry for use in diffi cult-to-machine

N/mm . 2 materials

micro cut edge treatment and special lapping

Execution: method for excellent process reliability and long No. 13446

right die. tol. 6 g with spiral point, nitrided, service life

pre-slotted and 2.0 pitch No. 13447: standard geometry with excellent

price/performance ratio

No. 13447

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13446

13447

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 264

0302_EN_2018_KERN[21847460]-l.indd 303 12/17/2018 3:32:27 PM