Page 268 - Icon Ridge Presents ATORN

P. 268

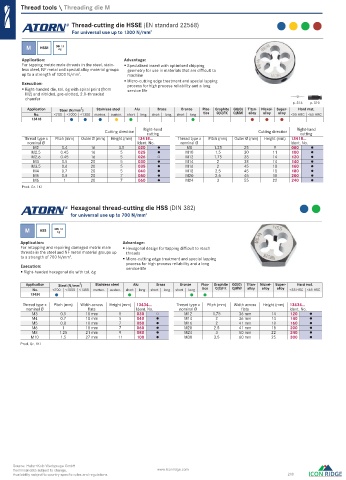

Thread tools \ Threading die M

Thread-cutting die HSSE ( EN standard 22568 )

For universal use up to 1300 N/mm 2

M HSSE DIN 13

6g

Application: Advantage:

For tapping metric male threads in the steel, stain- Specialised insert with optimised chipping

less steel, NF metal and special alloy material groups geometry for use in materials that are diffi cult to

up to a strength of 1300 N/mm . 2 machine

Execution: Micro-cutting edge treatment and special lapping

process for high process reliability and a long

Right-handed die, tol. 6g with spiral point (from service life

M2) and nitrided, pre-slotted, 2.0-threaded

chamfer

p. 316 p. 310

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13418

Cutting direction Right-hand Cutting direction Right-hand

cutting

cutting

Thread type x Pitch (mm) Outer Ø (mm) Height (mm) 13418... Thread type x Pitch (mm) Outer Ø (mm) Height (mm) 13418...

nominal Ø Ident. No. nominal Ø Ident. No.

M2 0.4 16 3.5 020 M8 1.25 25 9 080

M2.5 0.45 16 5 025 M10 1.5 30 11 100

M2.6 0.45 16 5 026 ○ M12 1.75 38 14 120

M3 0.5 20 5 030 M14 2 38 14 140

M3.5 0.6 20 5 035 M16 2 45 18 160

M4 0.7 20 5 040 M18 2.5 45 18 180

M5 0.8 20 7 050 M20 2.5 45 18 200

M6 1 20 7 060 M24 3 55 22 240

Prod. Gr. 1KI

Hexagonal thread-cutting die HSS ( DIN 382 )

for universal use up to 700 N/mm 2

M HSS DIN 13

6g

Application: Advantage:

For retapping and repairing damaged metric male Hexagonal design for tapping diffi cult to reach

threads in the steel and NF metal material groups up threads

to a strength of 700 N/mm . 2 Micro-cutting edge treatment and special lapping

Execution: process for high process reliability and a long

service life

Right-handed hexagonal die with tol. 6g

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13434

Thread type x Pitch (mm) Width across Height (mm) 13434... Thread type x Pitch (mm) Width across Height (mm) 13434...

nominal Ø fl ats Ident. No. nominal Ø fl ats Ident. No.

M3 0.5 18 mm 5 030 ○ M12 1.75 36 mm 14 120

M4 0.7 18 mm 5 040 M14 2 36 mm 14 140

M5 0.8 18 mm 7 050 M16 2 41 mm 18 160

M6 1 18 mm 7 060 M20 2.5 41 mm 18 200

M8 1.25 21 mm 9 080 M24 3 50 mm 22 240

M10 1.5 27 mm 11 100 M30 3.5 60 mm 25 300

Prod. Gr. 1KI

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 268

0308_EN_2018_KERN[21847471]-U.indd 308 12/17/2018 3:32:20 PM