Page 304 - Icon Ridge Presents ATORN

P. 304

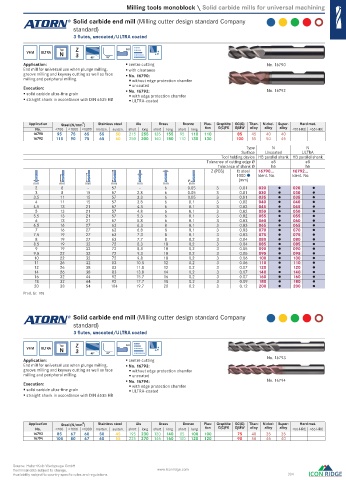

Milling tools monoblock \ Solid carbide mills for universal machining

Solid carbide end mill ( Milling cutter design standard Company

standard )

3 fl utes, uncoated/ULTRA coated

Typ Z HB

VHM ULTRA N 3 45°

Application: centre cutting No. 16790

End mill for universal use when plunge milling, with clearance

groove milling and keyway cutting as well as face No. 16790:

milling and peripheral milling. without edge protection chamfer

uncoated

Execution: No. 16792: No. 16792

solid carbide ultra-fi ne grain with edge protection chamfer

straight shank in accordance with DIN 6535 HB ULTRA-coated

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16790 95 75 65 55 50 215 255 135 155 95 110 110 85 45 40 40

16792 115 90 75 65 60 250 300 160 180 110 130 130 100 55 50 45

Type N N

Surface Uncoated ULTRA

Tool holding device HB parallel shank HB parallel shank

Tolerance of cutting edge Ø e8 e8

Tolerance of shank Ø h5 h5

Z (PCS) fz steel 16790... 16792...

1000 Ident. No. Ident. No.

(mm)

mm mm mm mm mm mm mm

2 8 - 57 - 6 0.05 3 0.01 020 020

3 8 15 57 2.8 6 0.05 3 0.01 030 030

3.5 11 15 57 3.3 6 0.05 3 0.01 035 035

4 11 15 57 3.8 6 0.1 3 0.02 040 040

4.5 13 21 57 4.3 6 0.1 3 0.02 045 045

5 13 21 57 4.8 6 0.1 3 0.02 050 050

5.5 13 21 57 5.3 6 0.1 3 0.02 055 055

6 13 21 57 5.8 6 0.1 3 0.03 060 060

6.5 16 27 63 6.3 8 0.1 3 0.03 065 065

7 16 27 63 6.8 8 0.1 3 0.03 070 070

7.5 19 27 63 7.3 8 0.1 3 0.03 075 075

8 19 27 63 7.7 8 0.2 3 0.04 080 080

8.5 19 32 72 8.3 10 0.2 3 0.04 085 085

9 19 32 72 8.8 10 0.2 3 0.05 090 090

9.5 22 32 72 9.3 10 0.2 3 0.05 095 095

10 22 32 72 9.8 10 0.2 3 0.06 100 100

11 26 32 83 10.8 12 0.2 3 0.06 110 110

12 26 38 83 11.8 12 0.2 3 0.07 120 120

14 26 38 83 13.8 14 0.2 3 0.07 140 140

16 32 44 92 15.7 16 0.2 3 0.07 160 160

18 32 44 92 17.7 18 0.2 3 0.09 180 180

20 38 54 104 19.7 20 0.2 3 0.12 200 200

Prod. Gr. 108

Solid carbide end mill ( Milling cutter design standard Company

standard )

3 fl utes, uncoated/ULTRA coated

Typ Z HB

VHM ULTRA N 3 45°

Application: centre cutting No. 16793

End mill for universal use when plunge milling, No. 16793:

groove milling and keyway cutting as well as face without edge protection chamfer

milling and peripheral milling. uncoated

Execution: No. 16794: No. 16794

with edge protection chamfer

solid carbide ultra-fi ne grain ULTRA-coated

straight shank in accordance with DIN 6535 HB

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16793 85 67 60 50 45 195 230 120 140 85 100 100 75 40 35 35

16794 105 80 67 60 55 225 270 145 160 100 120 120 90 50 45 40

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 304

0363_EN_2018_KERN[21847597]-j.indd 363 12/17/2018 3:32:23 PM