Page 307 - Icon Ridge Presents ATORN

P. 307

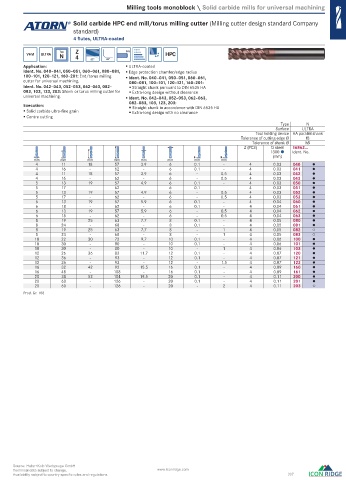

Milling tools monoblock \ Solid carbide mills for universal machining

Solid carbide HPC end mill/torus milling cutter ( Milling cutter design standard Company

standard )

4 fl utes, ULTRA-coated

Typ Z HA

VHM ULTRA N 4 45° HPC

Application: ULTRA-coated

Ident. No. 040–041, 050–051, 060–061, 080–081, Edge protection chamfer/edge radius

100–101, 120–121, 160–201: End/torus milling Ident. No. 040–041, 050–051, 060–061,

cutter for universal machining. 080–081, 100–101, 120–121, 160–201:

Ident. No. 042–043, 052–053, 062–063, 082– Straight shank pursuant to DIN 6535 HA

083, 103, 123, 203: Shank or torus milling cutter for Extra-long design without clearance

universal machining. Ident. No. 042–043, 052–053, 062–063,

Execution: 082–083, 103, 123, 203:

Straight shank in accordance with DIN 6535 HA

Solid carbide ultra-fi ne grain Extra-long design with no clearance

Centre cutting

Type N

Surface ULTRA

Tool holding device HA parallel shank

Tolerance of cutting edge Ø f8

Tolerance of shank Ø h5

Z (PCS) fz steel 16862...

1300 Ident. No.

(mm)

mm mm mm mm mm mm mm mm

4 11 18 57 3.9 6 0.1 - 4 0.03 040

4 16 - 62 - 6 0.1 - 4 0.03 041

4 11 18 57 3.9 6 - 0.5 4 0.03 042

4 16 - 62 - 6 - 0.5 4 0.03 043

5 13 19 57 4.9 6 0.1 - 4 0.03 050

5 17 - 62 - 6 0.1 - 4 0.03 051

5 13 19 57 4.9 6 - 0.5 4 0.03 052

5 17 - 62 - 6 - 0.5 4 0.03 053

6 13 19 57 5.9 6 0.1 - 4 0.04 060

6 18 - 62 - 6 0.1 - 4 0.04 061

6 13 19 57 5.9 6 - 0.5 4 0.04 062

6 18 - 62 - 6 - 0.5 4 0.04 063

8 19 25 63 7.7 8 0.1 - 4 0.05 080

8 24 - 68 - 8 0.1 - 4 0.05 081

8 19 25 63 7.7 8 - 1 4 0.05 082 ○

8 24 - 68 - 8 - 1 4 0.05 083 ○

10 22 30 72 9.7 10 0.1 - 4 0.06 100

10 30 - 80 - 10 0.1 - 4 0.06 101

10 30 - 80 - 10 - 1 4 0.06 103

12 26 36 83 11.7 12 0.1 - 4 0.07 120

12 36 - 93 - 12 0.1 - 4 0.07 121

12 36 - 93 - 12 - 1.5 4 0.07 123

16 32 42 92 15.5 16 0.1 - 4 0.09 160

16 48 - 108 - 16 0.1 - 4 0.09 161

20 38 52 104 19.5 20 0.1 - 4 0.11 200

20 60 - 126 - 20 0.1 - 4 0.11 201

20 60 - 126 - 20 - 2 4 0.11 203 ○

Prod. Gr. 108

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 307

0368_EN_2018_KERN[21847604]-j.indd 369 12/17/2018 3:32:19 PM