Page 319 - Icon Ridge Presents ATORN

P. 319

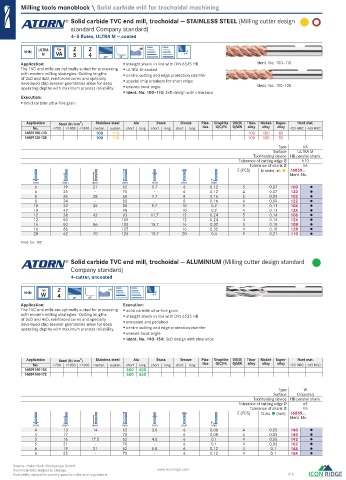

Milling tools monoblock \ Solid carbide mill for trochoidal machining

Solid carbide TVC end mill, trochoidal — STAINLESS STEEL ( Milling cutter design

standard Company standard )

4–5 fl utes, ULTRA M — coated

Typ

VHM ULTRA VA Z Z HB

M 5 4 45°

Application: straight shank in line with DIN 6535 HB Ident. No. 100–110

The TVC end mills are optimally suited for processing ULTRA M-coated

with modern milling strategies. Cutting lengths centre cutting and edge protection chamfer

of 3xD and 4xD, reinforced cores and specially

developed chip breaker geometries allow for deep special chip breakers for short chips Ident. No. 120–128

operating depths with maximum process reliability. uneven twist angle

Ident. No. 100–110: 3xD design with clearance

Execution:

solid carbide ultra-fi ne grain

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16859100-110 100 110 100 100 80

16859120-128 100 110 100 100 80

Type VA

Surface ULTRA M

Tool holding device HB parallel shank

Tolerance of cutting edge Ø h10

Tolerance of shank Ø h6

Z (PCS) fz steinl. st. 16859...

Ident. No.

mm mm mm mm mm mm mm

6 19 21 62 5.7 6 0.12 5 0.07 100

6 25 - 70 - 6 0.12 4 0.07 120

8 26 28 68 7.7 8 0.16 5 0.09 102

8 34 - 80 - 8 0.16 4 0.09 122

10 32 35 80 9.7 10 0.2 5 0.11 104

10 42 - 95 - 10 0.2 4 0.11 124

12 38 42 93 11.7 12 0.24 5 0.14 106

12 50 - 105 - 12 0.24 4 0.14 126

16 50 56 108 15.7 16 0.32 5 0.18 108

16 66 - 125 - 16 0.32 4 0.18 128

20 62 70 126 19.7 20 0.4 5 0.21 110

Prod. Gr. 152

Solid carbide TVC end mill, trochoidal — ALUMINIUM ( Milling cutter design standard

Company standard )

4-cutter, uncoated

Typ Z HB

VHM

W 4 45°

Application: Execution:

The TVC end mills are optimally suited for processing solid carbide ultra-fi ne grain

with modern milling strategies. Cutting lengths straight shank in line with DIN 6535 HB

of 3xD and 4xD, reinforced cores and specially uncoated and polished

developed chip breaker geometries allow for deep

operating depths with maximum process reliability. centre cutting and edge protection chamfer

uneven twist angle

Ident. No. 140–154: 3xD design with clearance

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16859140-154 600 400

16859160-172 500 360

Type W

Surface Uncoated

Tool holding device HB parallel shank

Tolerance of cutting edge Ø e8

Tolerance of shank Ø h5

Z (PCS) fz alu (mm) 16859...

Ident. No.

mm mm mm mm mm mm mm

4 13 14 62 3.8 6 0.08 4 0.05 140

4 17 - 70 - 6 0.08 4 0.05 160

5 16 17.5 62 4.8 6 0.1 4 0.06 142

5 21 - 70 - 6 0.1 4 0.06 162

6 19 21 62 5.8 6 0.12 4 0.1 144

6 25 - 70 - 6 0.12 4 0.1 164

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 319

0387_EN_2018_KERN[21847632]-j.indd 388 12/17/2018 3:32:29 PM