Page 323 - Icon Ridge Presents ATORN

P. 323

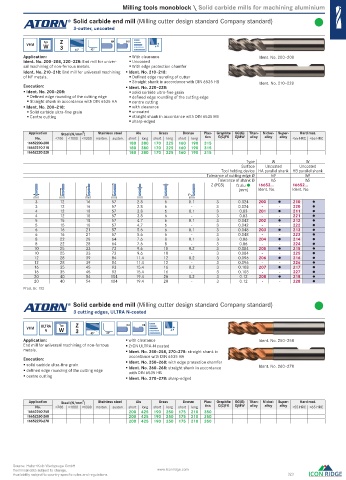

Milling tools monoblock \ Solid carbide mills for machining aluminium

Solid carbide end mill ( Milling cutter design standard Company standard )

3-cutter, uncoated

Typ Z HA HB

VHM W 3 45°

Application: With clearance Ident. No. 200–208

Ident. No. 200–208, 220–228: End mill for univer- Uncoated

sal machining of non-ferrous metals. With edge protection chamfer

Ident. No. 210–218: End mill for universal machining Ident. No. 210–218:

of NF metals. Defi ned edge rounding of cutter

Straight shank in accordance with DIN 6535 HB Ident. No. 210–228

Execution: Ident. No. 220–228:

Ident. No. 200–208: solid carbide ultra-fi ne grain

Defi ned edge rounding of the cutting edge defi ned edge rounding of the cutting edge

Straight shank in accordance with DIN 6535 HA centre cutting

Ident. No. 200–218: with clearance

Solid carbide ultra-fi ne grain uncoated

Centre cutting straight shank in accordance with DIN 6535 HB

sharp-edged

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16652200-208 180 380 170 225 160 190 315

16652210-218 180 380 170 225 160 190 315

16652220-228 180 380 170 225 160 190 315

Type W W

Surface Uncoated Uncoated

Tool holding device HA parallel shank HB parallel shank

Tolerance of cutting edge Ø h9 h9

Tolerance of shank Ø h5 h5

Z (PCS) fz alu 16652... 16652...

(mm) Ident. No. Ident. No.

mm mm mm mm mm mm mm

3 12 16 57 2.8 6 0.1 3 0.024 200 210

3 12 16 57 2.8 6 - 3 0.024 - - 220

4 12 18 57 3.8 6 0.1 3 0.03 201 211

4 12 18 57 3.8 6 - 3 0.03 - - 221

5 15 18 57 4.7 6 0.1 3 0.042 202 212

5 15 18 57 4.7 6 - 3 0.042 - - 222

6 16 21 57 5.6 6 0.1 3 0.048 203 213

6 16 21 57 5.6 6 - 3 0.048 - - 223

8 22 28 64 7.6 8 0.1 3 0.06 204 214

8 22 28 64 7.6 8 - 3 0.06 - - 224

10 25 33 73 9.6 10 0.2 3 0.084 205 215

10 25 33 73 9.6 10 - 3 0.084 - - 225

12 28 39 84 11.4 12 0.2 3 0.096 206 216

12 28 39 84 11.4 12 - 3 0.096 - - 226

16 35 45 93 15.4 16 0.2 3 0.108 207 217

16 35 45 93 15.4 16 - 3 0.108 - - 227

20 40 54 104 19.4 20 0.2 3 0.12 208 218

20 40 54 104 19.4 20 - 3 0.12 - - 228

Prod. Gr. 152

Solid carbide end mill ( Milling cutter design standard Company standard )

3 cutting edges, ULTRA N-coated

ULTRA Typ Z HA HB

VHM W

N 3 45°

Application: with clearance Ident. No. 250–258

End mill for universal machining of non-ferrous ZrCN ULTRA-N coated

metals. Ident. No. 250–258, 270–278: straight shank in

accordance with DIN 6535 HA

Execution: Ident. No. 250–268: with edge protection chamfer

solid carbide ultra-fi ne grain Ident. No. 260–278

defi ned edge rounding of the cutting edge Ident. No. 260–268: straight shank in accordance

with DIN 6535 HB

centre cutting Ident. No. 270–278: sharp-edged

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16652250-258 200 425 190 250 175 210 350

16652260-268 200 425 190 250 175 210 350

16652270-278 200 425 190 250 175 210 350

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 323

0393_EN_2018_KERN[21847641]-n.indd 393 12/17/2018 3:32:19 PM