Page 328 - Icon Ridge Presents ATORN

P. 328

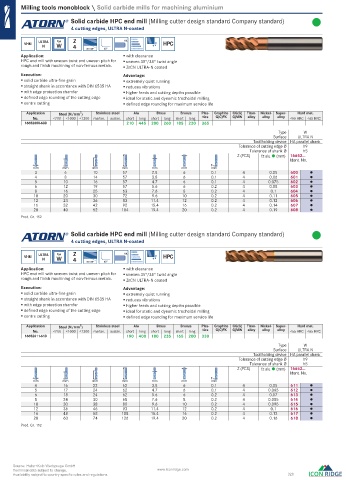

Milling tools monoblock \ Solid carbide mills for machining aluminium

Solid carbide HPC end mill ( Milling cutter design standard Company standard )

4 cutting edges, ULTRA N-coated

ULTRA Typ Z HA

VHM N W 4 35°/38° 45° HPC

Application: with clearance

HPC end mill with uneven twist and uneven pitch for uneven 35°/38° twist angle

rough and fi nish machining of non-ferrous metals. ZrCN ULTRA-N coated

Execution: Advantage:

solid carbide ultra-fi ne grain extremely quiet running

straight shank in accordance with DIN 6535 HA reduces vibrations

with edge protection chamfer higher feeds and cutting depths possible

defi ned edge rounding of the cutting edge ideal for static and dynamic trochoidal milling

centre cutting defi ned edge rounding for maximum service life

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16652600-608 210 445 200 260 185 220 365

Type W

Surface ULTRA N

Tool holding device HA parallel shank

Tolerance of cutting edge Ø h9

Tolerance of shank Ø h5

Z (PCS) fz alu (mm) 16652...

Ident. No.

mm mm mm mm mm mm mm

3 6 10 57 2.8 6 0.1 4 0.05 600

4 8 14 57 3.8 6 0.1 4 0.06 601

5 10 16 57 4.7 6 0.1 4 0.075 602

6 12 19 57 5.6 6 0.2 4 0.08 603

8 16 25 63 7.6 8 0.2 4 0.1 604

10 20 30 72 9.6 10 0.2 4 0.11 605

12 24 36 83 11.4 12 0.2 4 0.12 606

16 32 42 92 15.4 16 0.2 4 0.14 607

20 40 52 104 19.4 20 0.2 4 0.19 608

Prod. Gr. 152

Solid carbide HPC end mill ( Milling cutter design standard Company standard )

4 cutting edges, ULTRA N-coated

ULTRA Typ Z HA

VHM W HPC

N 4 35°/38° 45°

Application: with clearance

HPC end mill with uneven twist and uneven pitch for uneven 35°/38° twist angle

rough and fi nish machining of non-ferrous metals. ZrCN ULTRA-N coated

Execution: Advantage:

solid carbide ultra-fi ne grain extremely quiet running

straight shank in accordance with DIN 6535 HA reduces vibrations

with edge protection chamfer higher feeds and cutting depths possible

defi ned edge rounding of the cutting edge ideal for static and dynamic trochoidal milling

centre cutting defi ned edge rounding for maximum service life

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16652611-618 190 400 180 235 165 200 330

Type W

Surface ULTRA N

Tool holding device HA parallel shank

Tolerance of cutting edge Ø h9

Tolerance of shank Ø h5

Z (PCS) fz alu (mm) 16652...

Ident. No.

mm mm mm mm mm mm mm

4 16 22 62 3.8 6 0.1 4 0.05 611

5 17 24 62 4.7 6 0.1 4 0.065 612

6 18 24 62 5.6 6 0.2 4 0.07 613

8 24 30 68 7.6 8 0.2 4 0.085 614

10 30 38 80 9.6 10 0.2 4 0.095 615

12 36 46 93 11.4 12 0.2 4 0.1 616

16 48 58 108 15.4 16 0.2 4 0.12 617

20 60 74 126 19.4 20 0.2 4 0.16 618

Prod. Gr. 152

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 328

0398_EN_2018_KERN[21847649]-n.indd 398 12/17/2018 3:32:19 PM