Page 399 - Icon Ridge Presents ATORN

P. 399

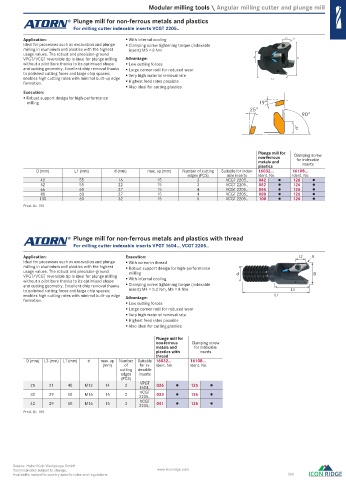

Modular milling tools \ Angular milling cutter and plunge mill

Plunge mill for non-ferrous metals and plastics

For milling cutter indexable inserts VCGT 2205..

Application: With internal cooling L2 R

Ideal for processes such as excavation and plunge Clamping screw tightening torque (indexable

milling in aluminium and plastics with the highest insert) M5 = 8 Nm

usage values. The robust and precision-ground

VPGT/VCGT reversible tip is ideal for plunge milling Advantage: d D

without a pilot bore thanks to its optimised shape Low cutting forces

and cutting geometry. Excellent chip removal thanks Large corner radii for reduced wear

to polished cutting faces and large chip spaces; Very high material removal rate

enables high cutting rates with minimal built-up edge L1

formation. Highest feed rates possible

Also ideal for cutting plastics

Execution:

Robust support design for high-performance

milling 19°

25°

90°

l 2

Plunge mill for Clamping screw

non-ferrous

metals and for indexable

plastics inserts

D (mm) L1 (mm) d (mm) max. ap (mm) Number of cutting Suitable for index- 16032... 16108...

edges (PCS) able inserts Ident. No. Ident. No.

42 55 16 15 3 VCGT 2205.. 042 126

52 55 22 15 3 VCGT 2205.. 052 126

66 60 27 15 4 VCGT 2205.. 066 126

80 60 27 15 4 VCGT 2205.. 080 126

100 60 32 15 5 VCGT 2205.. 100 126

Prod. Gr. 155

Plunge mill for non-ferrous metals and plastics with thread

For milling cutter indexable inserts VPGT 1604.., VCGT 2205..

Application: Execution: L2 R

Ideal for processes such as excavation and plunge With screw-in thread

milling in aluminium and plastics with the highest Robust support design for high-performance

usage values. The robust and precision-ground milling

VPGT/VCGT reversible tip is ideal for plunge milling d D

without a pilot bore thanks to its optimised shape With internal cooling

and cutting geometry. Excellent chip removal thanks Clamping screw tightening torque (indexable

to polished cutting faces and large chip spaces; insert) M4 = 5.2 Nm, M5 = 8 Nm L3

enables high cutting rates with minimal built-up edge Advantage: L1

formation.

Low cutting forces

Large corner radii for reduced wear

Very high material removal rate

Highest feed rates possible

Also ideal for cutting plastics

Plunge mill for

non-ferrous Clamping screw

metals and for indexable

plastics with inserts

thread

D (mm) L3 (mm) L1 (mm) d max. ap Number Suitable 16032... 16108...

(mm) of for in- Ident. No. Ident. No.

cutting dexable

edges inserts

(PCS)

VPGT

25 21 40 M12 14 2 1604.. 026 125

VCGT

32 29 50 M16 15 2 2205.. 033 126

VCGT

42 29 50 M16 15 3 2205.. 041 126

Prod. Gr. 155

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 399

0495_EN_2018_KERN[21847525]-V.indd 495 12/17/2018 3:32:45 PM