Page 507 - Icon Ridge Presents ATORN

P. 507

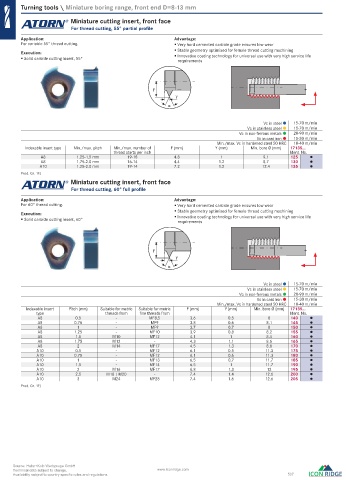

Turning tools \ Miniature boring range, front end D=8-13 mm

Miniature cutting insert, front face

For thread cutting, 55° partial profi le

Application: Advantage:

For variable 55° thread cutting. Very hard cemented carbide grade ensures low wear

Stable geometry optimised for female thread cutting machining

Execution:

Solid carbide cutting insert, 55° Innovative coating technology for universal use with very high service life

requirements

F

Y

Vc in steel 15-70 m/min

Vc in stainless steel 15-70 m/min

Vc in non-ferrous metals 20-90 m/min

Vc in cast iron 15-30 m/min

Min./max. Vc in hardened steel 50 HRC 10-40 m/min

Indexable insert type Min./max. pitch Min./max. number of F (mm) Y (mm) Min. bore Ø (mm) 17135...

thread starts per inch Ident. No.

A8 1.25-1.5 mm 19-18 4.8 1 9.1 125

A8 1.75-2.0 mm 16-14 4.4 1.2 8.7 130

A10 1.25-2.0 mm 19-14 7.2 1.2 12.4 135

Prod. Gr. 1FJ

Miniature cutting insert, front face

For thread cutting, 60° full profi le

Application: Advantage:

For 60° thread cutting. Very hard cemented carbide grade ensures low wear

Stable geometry optimised for female thread cutting machining

Execution:

Solid carbide cutting insert, 60° Innovative coating technology for universal use with very high service life

requirements

F

Y

Vc in steel 15-70 m/min

Vc in stainless steel 15-70 m/min

Vc in non-ferrous metals 20-90 m/min

Vc in cast iron 15-30 m/min

Min./max. Vc in hardened steel 50 HRC 10-40 m/min

Indexable insert Pitch (mm) Suitable for metric Suitable for metric F (mm) Y (mm) Min. bore Ø (mm) 17135...

type threads from fi ne threads from Ident. No.

A8 0.5 - MF8,5 3.6 0.5 8 140

A8 0.75 - MF9 3.8 0.6 8.1 145

A8 1 - MF9 3.7 0.7 8 150

A8 1.25 - MF10 3.9 0.8 8.2 155

A8 1.5 M10 MF12 4.1 1 8.4 160

A8 1.75 M12 - 4.3 1.1 8.6 165

A8 2 M14 MF17 4.5 1.3 8.8 170

A10 0.5 - MF12 6.1 0.5 11.3 175

A10 0.75 - MF12 6.1 0.6 11.3 180

A10 1 - MF13 6.5 0.7 11.7 185

A10 1.5 - MF14 6.5 1 11.7 190

A10 2 M16 MF17 6.8 1.3 12 195

A10 2.5 M18 | M20 - 7.4 1.4 12.6 200

A10 3 M24 MF28 7.4 1.6 12.6 205

Prod. Gr. 1FJ

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 507

0639_EN_2018_KERN[21847967]-v.indd 640 12/17/2018 3:33:39 PM