Page 60 - Icon Ridge Presents ATORN

P. 60

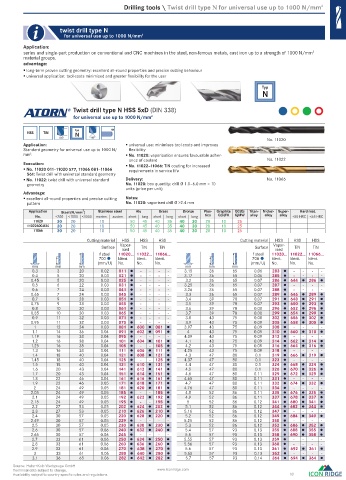

Drilling tools \ Twist drill type N for universal use up to 1000 N/mm 2

twist drill type N

for universal use up to 1000 N/mm 2

Application:

series and single-part production on conventional and CNC machines in the steel, non-ferrous metals, cast iron up to a strength of 1000 N/mm

2

material groups.

advantage:

long-term proven cutting geometry: excellent all-round properties and precise cutting behaviour

universal application: tool costs minimised and greater fl exibility for the user

Typ

N

Twist drill type N HSS 5xD ( DIN 338 )

for universal use up to 1000 N/mm 2

Typ HA

HSS TiN N

5xD 118° No. 11020

Application: universal use: minimises tool costs and improves

Standard geometry for universal use up to 1000 N/ fl exibility

mm . 2 No. 11020: vaporisation ensures favourable adher-

ence of coolant No. 11022

Execution: No. 11022–11066: TiN coating for increased

No. 11020 011–11020 577, 11066 081–11066 requirements in service life

561: Twist drill with universal standard geometry

No. 11022: twist drill with universal standard Delivery: No. 11066

geometry No. 11020: box quantity: drill Ø 1.0–6.0 mm = 10

units (price per unit)

Advantage:

excellent all-round properties and precise cutting Notes:

pattern No. 11020: vaporised drill Ø >2.4 mm

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11020 30 20 10 50 45 40 35 40 30 20 10 25

11022600-834 30 20 10 50 45 40 35 40 30 20 10 25

11066 30 20 10 50 45 40 35 40 30 20 10 25

Cutting material HSS HSS HSS Cutting material HSS HSS HSS

Surface Vapor- TiN TiN Surface Vapor- TiN TiN

ised

ised

f steel 11020... 11022... 11066... f steel 11020... 11022... 11066...

700 Ident. Ident. Ident. 700 Ident. Ident. Ident.

(mm/U) No. No. No. (mm/U) No. No. No.

mm mm mm mm mm mm

0.3 3 20 0.02 011 - - - - 3.15 36 65 0.06 283 - - - -

0.4 5 20 0.03 021 - - - - 3.17 36 65 0.06 285 - - - -

0.45 5 20 0.03 025 - - - - 3.2 36 65 0.07 286 644 286

0.5 6 22 0.03 031 - - - - 3.25 36 65 0.07 287 - - - -

0.6 7 24 0.03 041 - - - - 3.26 36 65 0.07 288 - - - -

0.65 7 24 0.03 045 - - - - 3.3 36 65 0.07 289 646 289

0.7 9 28 0.03 051 - - - - 3.4 39 70 0.07 291 648 291

0.75 9 28 0.03 055 - - - - 3.5 39 70 0.07 293 650 293

0.8 10 30 0.03 061 - - - - 3.6 39 70 0.08 296 652 296

0.85 10 30 0.03 065 - - - - 3.7 39 70 0.08 299 654 299

0.9 11 32 0.03 071 - - - - 3.8 43 75 0.08 302 656 302

0.95 11 32 0.03 075 - - - - 3.9 43 75 0.09 305 658 305

1 12 34 0.03 081 600 081 3.97 43 75 0.09 308 - - - -

1.1 14 36 0.04 091 602 091 4 43 75 0.09 310 660 310

1.19 16 38 0.04 095 - - - - 4.09 43 75 0.09 312 - - - -

1.2 16 38 0.04 101 604 101 4.1 43 75 0.09 314 662 314

1.25 16 38 0.04 105 - - 105 4.2 43 75 0.09 316 664 316

1.3 16 38 0.04 111 606 111 4.25 43 75 0.09 318 - - - -

1.4 18 40 0.04 121 608 121 4.3 47 80 0.1 319 666 319

1.45 18 40 0.04 125 - - 125 4.37 47 80 0.1 323 - - - -

1.5 18 40 0.04 131 610 131 4.4 47 80 0.1 324 668 324

1.6 20 43 0.04 141 612 141 4.5 47 80 0.1 326 670 326

1.7 20 43 0.04 151 614 151 4.6 47 80 0.11 329 672 329

1.8 22 46 0.04 161 616 161 4.65 47 80 0.11 331 - - - -

1.9 22 46 0.05 171 618 171 4.7 47 80 0.11 332 674 332

2 24 49 0.05 181 620 181 4.76 47 80 0.11 334 - - - -

2.05 24 49 0.05 185 - - 185 4.8 52 86 0.11 335 676 335

2.1 24 49 0.05 192 622 192 4.9 52 86 0.11 337 678 337

2.15 24 49 0.05 195 - - 195 5 52 86 0.12 341 680 341

2.2 27 53 0.05 202 624 202 5.1 52 86 0.12 344 682 344

2.3 27 53 0.05 210 626 210 5.16 52 86 0.12 347 - - - -

2.4 30 57 0.05 220 628 220 5.2 52 86 0.12 349 684 349

2.49 30 57 0.05 229 - - - - 5.25 52 86 0.12 350 - - - -

2.5 30 57 0.05 230 630 230 5.3 52 86 0.12 352 686 352

2.6 30 57 0.06 240 632 240 5.4 57 93 0.13 355 688 355

2.65 30 57 0.06 245 - - - - 5.5 57 93 0.13 358 690 358

2.7 33 61 0.06 250 634 250 5.55 57 93 0.13 359 - - - -

2.8 33 61 0.06 260 636 260 5.56 57 93 0.13 360 - - - -

2.9 33 61 0.06 270 638 270 5.6 57 93 0.13 361 692 361

3 33 61 0.06 280 640 280 5.65 57 93 0.13 362 - - - -

3.1 36 65 0.06 282 642 282 5.7 57 93 0.14 364 694 364

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 60

0067_EN_2018_KERN[21841774]-n.indd 69 12/17/2018 3:31:31 PM