Page 64 - Icon Ridge Presents ATORN

P. 64

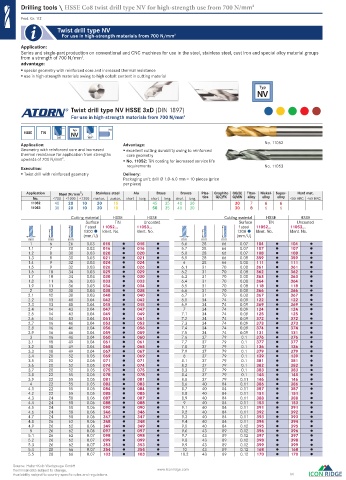

Drilling tools \ HSSE Co8 twist drill type NV for high-strength use from 700 N/mm 2

Prod. Gr. 112

Twist drill type NV

For use in high-strength materials from 700 N/mm 2

Application:

Series and single-part production on conventional and CNC machines for use in the steel, stainless steel, cast iron and special alloy material groups

from a strength of 700 N/mm .

2

advantage:

special geometry with reinforced core and increased thermal resistance

use in high-strength materials owing to high cobalt content in cutting material

Typ

NV

Twist drill type NV HSSE 3xD ( DIN 1897 )

For use in high-strength materials from 700 N/mm 2

Typ HA

HSSE TiN NV

3xD 130°

Application: Advantage: No. 11052

Geometry with reinforced core and increased excellent cutting durability owing to reinforced

thermal resistance for application from strengths core geometry

upwards of 700 N/mm . 2 No. 11052: TiN coating for increased service life

Execution: requirements No. 11053

Twist drill with reinforced geometry Delivery:

Packaging unit: drill Ø 1.0-6.0 mm = 10 pieces (price

per piece)

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11052 40 20 10 20 15 45 35 40 30 30 7 6 6

11053 30 20 10 20 10 50 35 40 30 30 8 6 6

Cutting material HSSE HSSE Cutting material HSSE HSSE

Surface TiN Uncoated Surface TiN Uncoated

f steel 11052... 11053... f steel 11052... 11053...

1300 Ident. No. Ident. No. 1300 Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

1 6 26 0.03 015 015 5.6 28 66 0.07 104 104

1.1 7 28 0.03 016 016 5.7 28 66 0.07 107 107

1.2 8 30 0.03 020 020 5.8 28 66 0.07 108 108

1.3 8 30 0.03 021 021 5.9 28 66 0.08 359 359

1.4 9 32 0.03 024 024 6 28 66 0.08 111 111

1.5 9 32 0.03 026 026 6.1 31 70 0.08 361 361

1.6 10 34 0.03 029 029 6.2 31 70 0.08 362 362

1.7 10 34 0.03 030 030 6.3 31 70 0.08 363 363

1.8 11 36 0.03 033 033 6.4 31 70 0.08 364 364

1.9 11 36 0.03 034 034 6.5 31 70 0.08 118 118

2 12 38 0.03 038 038 6.6 31 70 0.08 366 366

2.1 12 38 0.03 040 040 6.7 31 70 0.08 367 367

2.2 13 40 0.04 042 042 6.8 34 74 0.09 122 122

2.3 13 40 0.04 045 045 6.9 34 74 0.09 369 369

2.4 14 43 0.04 047 047 7 34 74 0.09 124 124

2.5 14 43 0.04 049 049 7.1 34 74 0.09 125 125

2.6 14 43 0.04 051 051 7.2 34 74 0.09 372 372

2.7 16 46 0.04 053 053 7.3 34 74 0.09 373 373

2.8 16 46 0.04 056 056 7.4 34 74 0.09 374 374

2.9 16 46 0.04 059 059 7.5 34 74 0.09 131 131

3 16 46 0.04 060 060 7.6 37 79 0.1 376 376

3.1 18 49 0.04 061 061 7.7 37 79 0.1 377 377

3.2 18 49 0.04 065 065 7.8 37 79 0.1 136 136

3.3 18 49 0.04 067 067 7.9 37 79 0.1 379 379

3.4 20 52 0.05 069 069 8 37 79 0.1 139 139

3.5 20 52 0.05 071 071 8.1 37 79 0.1 381 381

3.6 20 52 0.05 074 074 8.2 37 79 0.1 382 382

3.7 20 52 0.05 075 075 8.3 37 79 0.1 383 383

3.8 22 55 0.05 078 078 8.4 37 79 0.1 145 145

3.9 22 55 0.05 081 081 8.5 37 79 0.11 146 146

4 22 55 0.05 083 083 8.6 40 84 0.11 386 386

4.1 22 55 0.05 084 084 8.7 40 84 0.11 387 387

4.2 22 55 0.05 085 085 8.8 40 84 0.11 151 151

4.3 24 58 0.06 087 087 8.9 40 84 0.11 388 388

4.4 24 58 0.06 088 088 9 40 84 0.11 153 153

4.5 24 58 0.06 090 090 9.1 40 84 0.11 391 391

4.6 24 58 0.06 346 346 9.2 40 84 0.11 392 392

4.7 24 58 0.06 347 347 9.3 40 84 0.11 393 393

4.8 26 62 0.06 348 348 9.4 40 84 0.11 394 394

4.9 26 62 0.06 349 349 9.5 40 84 0.12 395 395

5 26 62 0.06 097 097 9.6 43 89 0.12 396 396

5.1 26 62 0.07 098 098 9.7 43 89 0.12 397 397

5.2 26 62 0.07 099 099 9.8 43 89 0.12 398 398

5.3 26 62 0.07 353 353 9.9 43 89 0.12 399 399

5.4 28 66 0.07 354 354 10 43 89 0.12 168 168

5.5 28 66 0.07 103 103 10.2 43 89 0.12 170 170

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 64

0067_EN_2018_KERN[21841774]-n.indd 74 12/17/2018 3:31:47 PM