Page 68 - Icon Ridge Presents ATORN

P. 68

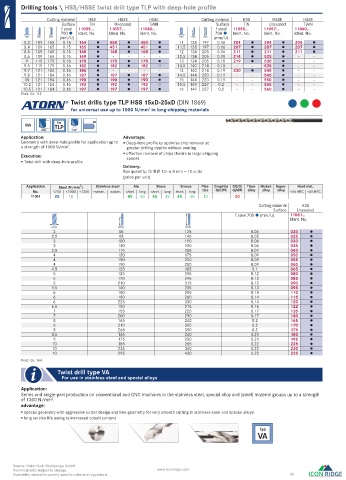

Drilling tools \ HSS/HSSE twist drill type TLP with deep-hole profi le

Cutting material HSS HSSE HSSE Cutting material HSS HSSE HSSE

Surface TiN Uncoated TiAlN Surface TiN Uncoated TiAlN

f steel 11055... 11057... 11060... f steel 11055... 11057... 11060...

700 Ident. No. Ident. No. Ident. No. 700 Ident. No. Ident. No. Ident. No.

mm mm mm (mm/U) mm mm mm (mm/U)

8.3 109 165 0.15 164 450 450 11 128 197 0.16 204 204 204

8.4 109 165 0.15 165 451 451 11.5 128 197 0.16 207 207 207

8.5 109 165 0.15 168 168 168 12 134 205 0.16 211 211 211

8.6 109 165 0.15 169 - - - - 12.5 134 205 0.18 214 525 - -

9 115 175 0.16 175 175 175 13 134 205 0.18 219 530 - -

9.5 115 175 0.16 182 182 182 ○ 13.5 140 214 0.18 - - 535 - -

9.7 121 184 0.16 186 - - - - 14 140 214 0.19 230 540 - -

9.8 121 184 0.16 187 187 187 14.5 144 220 0.19 - - 545 - -

10 121 184 0.16 190 190 190 15 144 220 0.19 - - 550 - -

10.2 121 184 0.16 192 192 192 ○ 15.5 149 227 0.2 - - 555 - -

10.5 121 184 0.16 197 197 197 16 149 227 0.2 - - 560 - -

Prod. Gr. 112

Twist drills type TLP HSS 15xD-25xD ( DIN 1869 )

for universal use up to 1000 N/mm in long-chipping materials

2

Typ HA

HSS TLP

15xD 130°

Application: Advantage:

Geometry with deep-hole profi le for application up to Deep-hole profi le to optimise chip removal at

a strength of 1000 N/mm . 2 greater drilling depths without venting

Execution: eff ective removal of chips thanks to large chipping

spaces

Twist drill with deep-hole profi le

Delivery:

Box quantity: Drill Ø 1.0–6.0 mm = 10 units

(price per unit)

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11061 25 10 40 50 45 35 40 30 10 20

Cutting material HSS

Surface Uncoated

f steel 700 (mm/U) 11061...

Ident. No.

mm mm mm

2 85 125 0.05 020

2.5 95 140 0.05 025

3 100 150 0.06 030

3 130 190 0.06 035

3.5 115 165 0.07 040

4 120 175 0.09 050

4 150 220 0.09 055

4 190 280 0.09 060

4.5 125 185 0.1 065

5 135 195 0.12 080

5 170 245 0.12 085

5 210 315 0.12 090

5.5 140 205 0.13 095

6 140 205 0.14 110

6 180 260 0.14 115

6 225 330 0.14 120

6.5 150 215 0.16 122

7 155 225 0.17 135

7 200 290 0.17 140

8 165 240 0.2 165

8 210 305 0.2 170

8 265 390 0.2 175

8.5 165 240 0.21 180

9 175 250 0.21 195

10 185 265 0.22 225

10 235 340 0.22 230

10 295 430 0.22 235

Prod. Gr. 1AA

Twist drill type VA

For use in stainless steel and special alloys

Application:

Series and single-part production on conventional and CNC machines in the stainless steel, special alloy and (steel) material groups up to a strength

of 1300 N/mm . 2

advantage:

special geometry with aggressive cutter design and free geometry for very smooth cutting in stainless steel and special alloys

long service life owing to increased cobalt content

Typ

VA

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 68

0067_EN_2018_KERN[21841774]-n.indd 78 12/17/2018 3:31:59 PM