Page 71 - Icon Ridge Presents ATORN

P. 71

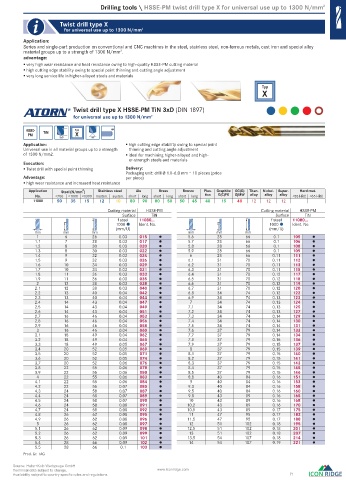

Drilling tools \ HSSE-PM twist drill type X for universal use up to 1300 N/mm 2

Twist drill type X

for universal use up to 1300 N/mm 2

Application:

Series and single-part production on conventional and CNC machines in the steel, stainless steel, non-ferrous metals, cast iron and special alloy

material groups up to a strength of 1300 N/mm .

2

advantage:

very high wear resistance and heat resistance owing to high-quality HSSE-PM cutting material

high cutting edge stability owing to special point thinning and cutting angle adjustment

very long service life in higher-alloyed steels and materials

Typ

X

Twist drill type X HSSE-PM TiN 3xD ( DIN 1897 )

for universal use up to 1300 N/mm 2

HSSE- TiN Typ HA

PM X

3xD 118°

Application: high cutting edge stability owing to special point

Universal use in all material groups up to a strength thinning and cutting angle adjustment

of 1300 N/mm2. ideal for machining higher-alloyed and high-

Execution: er-strength steels and materials

Twist drill with special point thinning Delivery:

Packaging unit: drill Ø 1.0-6.0 mm = 10 pieces (price

Advantage: per piece)

high wear resistance and increased heat resistance

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11080 50 35 15 12 10 80 90 80 50 50 45 40 15 40 12 12 12

Cutting material HSSE-PM Cutting material HSSE-PM

Surface TiN Surface TiN

f steel 11080... f steel 11080...

1000 Ident. No. 1000 Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

1 6 26 0.03 015 5.6 28 66 0.1 105

1.1 7 28 0.03 017 5.7 28 66 0.1 106

1.2 8 30 0.03 020 5.8 28 66 0.1 108

1.3 8 30 0.03 022 5.9 28 66 0.1 109

1.4 9 32 0.03 024 6 28 66 0.11 111

1.5 9 32 0.03 026 6.1 31 70 0.11 112

1.6 10 34 0.03 029 6.2 31 70 0.11 113

1.7 10 34 0.03 031 6.3 31 70 0.11 115

1.8 11 36 0.03 033 6.4 31 70 0.12 117

1.9 11 36 0.03 035 6.5 31 70 0.12 118

2 12 38 0.03 038 6.6 31 70 0.12 119

2.1 12 38 0.03 040 6.7 31 70 0.12 120

2.2 13 40 0.04 042 6.8 34 74 0.12 122

2.3 13 40 0.04 044 6.9 34 74 0.13 123

2.4 14 43 0.04 047 7 34 74 0.13 124

2.5 14 43 0.04 049 7.1 34 74 0.13 125

2.6 14 43 0.04 051 7.2 34 74 0.13 127

2.7 16 46 0.04 053 7.3 34 74 0.14 129

2.8 16 46 0.04 056 7.4 34 74 0.14 130

2.9 16 46 0.04 058 7.5 34 74 0.14 131

3 16 46 0.04 060 7.6 37 79 0.14 133

3.1 18 49 0.04 062 7.7 37 79 0.14 134

3.2 18 49 0.04 065 7.8 37 79 0.15 136

3.3 18 49 0.05 067 7.9 37 79 0.15 137

3.4 20 52 0.05 069 8 37 79 0.15 139

3.5 20 52 0.05 071 8.1 37 79 0.15 140

3.6 20 52 0.05 074 8.2 37 79 0.15 141

3.7 20 52 0.06 076 8.3 37 79 0.15 143

3.8 22 55 0.06 078 8.4 37 79 0.15 145

3.9 22 55 0.06 080 8.5 37 79 0.15 146

4 22 55 0.06 083 8.8 40 84 0.16 151

4.1 22 55 0.06 084 9 40 84 0.16 153

4.2 22 55 0.07 085 9.3 40 84 0.16 158

4.3 24 58 0.07 087 9.5 40 84 0.16 160

4.4 24 58 0.07 089 9.8 43 89 0.16 165

4.5 24 58 0.07 090 10 43 89 0.16 168

4.6 24 58 0.08 091 10.2 43 89 0.16 170

4.7 24 58 0.08 092 10.5 43 89 0.17 175

4.8 26 62 0.08 095 11 47 95 0.17 182

4.9 26 62 0.08 096 11.5 47 95 0.17 188

5 26 62 0.08 097 12 51 102 0.18 195

5.1 26 62 0.09 098 12.5 51 102 0.18 201

5.2 26 62 0.09 099 13 51 102 0.18 207

5.3 26 62 0.09 101 13.5 54 107 0.18 214

5.4 28 66 0.09 102 14 54 107 0.19 221

5.5 28 66 0.1 103

Prod. Gr. 1AG

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 71

0081_EN_2018_KERN[21841791]-r.indd 81 12/17/2018 3:31:08 PM