Page 70 - Icon Ridge Presents ATORN

P. 70

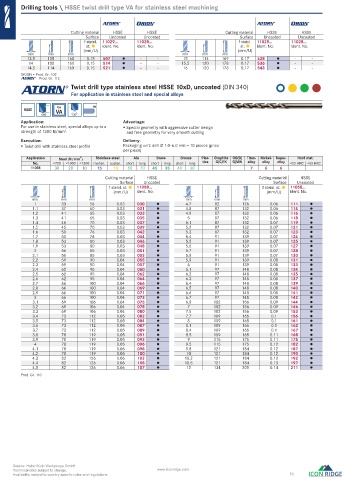

Drilling tools \ HSSE twist drill type VA for stainless steel machining

Cutting material HSSE HSSE Cutting material HSSE HSSE

Surface Uncoated Uncoated Surface Uncoated Uncoated

f steinl. 11029... 11028... f steinl. 11029... 11028...

st. Ident. No. Ident. No. st. Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

13.5 108 160 0.15 507 - - 15 114 169 0.17 528 - -

14 108 160 0.15 514 - - 15.5 120 178 0.17 536 - -

14.5 114 169 0.15 521 - - 16 120 178 0.17 543 - -

ORION = Prod. Gr. 102

a = Prod. Gr. 112

Twist drill type stainless steel HSSE 10xD, uncoated ( DIN 340 )

For application in stainless steel and special alloys

Typ HA

HSSE VA

10xD 130°

Application: Advantage:

For use in stainless steel, special alloys up to a Special geometry with aggressive cutter design

strength of 1300 N/mm . 2 and free geometry for very smooth cutting

Execution: Delivery:

Twist drill with stainless steel profi le Packaging unit: drill Ø 1.0-6.0 mm = 10 pieces (price

per piece)

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11058 30 20 10 15 10 50 70 45 35 40 30 7 6 6

Cutting material HSSE Cutting material HSSE

Surface Uncoated Surface Uncoated

f steinl. st. 11058... f steinl. st. 11058...

(mm/U) Ident. No. (mm/U) Ident. No.

mm mm mm mm mm mm

1 33 56 0.03 030 4.7 82 126 0.06 111

1.1 37 60 0.03 031 4.8 87 132 0.06 114

1.2 41 65 0.03 033 4.9 87 132 0.06 116

1.3 41 65 0.03 035 5 87 132 0.06 118

1.4 45 70 0.03 037 5.1 87 132 0.07 119

1.5 45 70 0.03 039 5.2 87 132 0.07 121

1.6 50 76 0.03 042 5.3 87 132 0.07 123

1.7 50 76 0.03 044 5.4 91 139 0.07 124

1.8 53 80 0.03 046 5.5 91 139 0.07 125

1.9 53 80 0.03 048 5.6 91 139 0.07 127

2 56 85 0.03 051 5.7 91 139 0.07 128

2.1 56 85 0.03 053 5.8 91 139 0.07 130

2.2 59 90 0.04 055 5.9 91 139 0.08 131

2.3 59 90 0.04 057 6 91 139 0.08 133

2.4 62 95 0.04 060 6.1 97 148 0.08 134

2.5 62 95 0.04 062 6.2 97 148 0.08 135

2.6 62 95 0.04 064 6.3 97 148 0.08 137

2.7 66 100 0.04 066 6.4 97 148 0.08 139

2.8 66 100 0.04 069 6.5 97 148 0.08 140

2.9 66 100 0.04 071 6.6 97 148 0.08 141

3 66 100 0.04 073 6.7 97 148 0.08 142

3.1 69 106 0.04 075 6.8 102 156 0.09 144

3.2 69 106 0.04 078 7 102 156 0.09 146

3.3 69 106 0.04 080 7.5 102 156 0.09 153

3.4 73 112 0.05 082 7.7 109 165 0.1 156

3.5 73 112 0.05 084 8 109 165 0.1 161

3.6 73 112 0.05 087 8.1 109 165 0.1 162

3.7 73 112 0.05 089 8.4 109 165 0.1 167

3.8 78 119 0.05 091 8.5 109 165 0.11 168

3.9 78 119 0.05 093 9 115 175 0.11 175

4 78 119 0.05 096 9.5 115 175 0.12 182

4.1 78 119 0.05 098 9.8 121 184 0.12 187

4.2 78 119 0.05 100 10 121 184 0.12 190

4.3 82 126 0.06 102 10.2 121 184 0.12 192

4.4 82 126 0.06 105 10.5 121 184 0.13 197

4.5 82 126 0.06 107 12 134 205 0.14 211

Prod. Gr. 110

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 70

0079_EN_2018_KERN[21841788]-k.indd 80 12/17/2018 3:31:06 PM