Page 66 - Icon Ridge Presents ATORN

P. 66

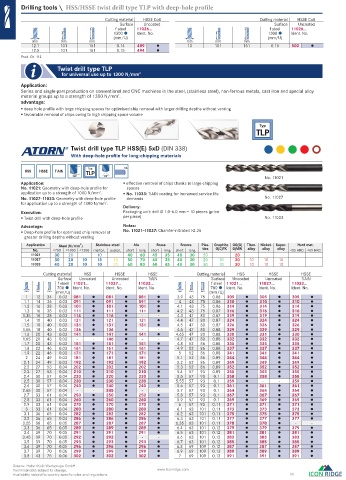

Drilling tools \ HSS/HSSE twist drill type TLP with deep-hole profile

Cutting material HSSE Co8 Cutting material HSSE Co8

Surface Uncoated Surface Uncoated

f steel 11026... f steel 11026...

1300 Ident. No. 1300 Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

12.1 101 151 0.14 489 13 101 151 0.15 500

12.5 101 151 0.15 494

Prod. Gr. 112

Twist drill type TLP

for universal use up to 1300 N/mm 2

Application:

Series and single-part production on conventional and CNC machines in the steel, (stainless steel), non-ferrous metals, cast iron and special alloy

material groups up to a strength of 1300 N/mm .

2

advantage:

deep hole profi le with large chipping spaces for optimised chip removal with larger drilling depths without venting

favourable removal of chips owing to high chipping space volume

Typ

TLP

Twist drill type TLP HSS(E) 5xD ( DIN 338 )

With deep-hole profi le for long-chipping materials

Typ HA

HSS HSSE TiAlN TLP

5xD 130° No. 11021

Application: eff ective removal of chips thanks to large chipping

No. 11021: Geometry with deep-hole profi le for spaces

application up to a strength of 1000 N/mm . 2 No. 11033: TiAlN coating for increased service life

No. 11027–11033: Geometry with deep-hole profi le demands No. 11027

for application up to a strength of 1300 N/mm . 2

Delivery:

Execution: Packaging unit: drill Ø 1.0-6.0 mm = 10 pieces (price

Twist drill with deep-hole profi le per piece) No. 11033

Advantage: Notes:

Deep-hole profi le for optimised chip removal at No. 11021–11027: Chamfer-nitrated >2.36

greater drilling depths without venting

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11021 30 20 10 40 60 45 35 40 30 20 20

11027 30 20 10 15 10 50 70 45 35 40 30 20 10 30 10 10 10

11033 40 20 10 10 20 60 80 60 45 40 30 30 10 30 10 10 10

Cutting material HSS HSSE HSSE Cutting material HSS HSSE HSSE

Surface Uncoated Uncoated TiAlN Surface Uncoated Uncoated TiAlN

f steel 11021... 11027... 11033... f steel 11021... 11027... 11033...

700 Ident. No. Ident. No. Ident. No. 700 Ident. No. Ident. No. Ident. No.

mm mm mm (mm/U) mm mm mm (mm/U)

1 12 34 0.03 081 081 081 3.9 43 75 0.06 305 305 305

1.1 14 36 0.03 091 091 091 4 43 75 0.06 310 310 310

1.2 16 38 0.03 101 101 101 4.1 43 75 0.06 314 314 314

1.3 16 38 0.03 111 111 111 4.2 43 75 0.07 316 316 316

1.35 16 38 0.03 114 116 - - 4.3 47 80 0.07 319 319 319

1.4 18 40 0.03 121 121 121 4.4 47 80 0.07 324 324 324

1.5 18 40 0.03 131 131 131 4.5 47 80 0.07 326 326 326

1.55 18 40 0.03 136 136 - - 4.6 47 80 0.08 329 329 329

1.6 20 43 0.03 141 141 141 4.65 47 80 0.08 330 331 330

1.65 20 43 0.03 - - 146 - - 4.7 47 80 0.08 332 332 332

1.7 20 43 0.03 151 151 151 4.8 52 86 0.08 335 335 335

1.8 22 46 0.03 161 161 161 4.9 52 86 0.08 337 337 337

1.9 22 46 0.03 171 171 171 5 52 86 0.08 341 341 341

2 24 49 0.03 181 181 181 5.1 52 86 0.09 344 344 344

2.1 24 49 0.03 192 192 192 5.2 52 86 0.09 349 349 349

2.2 27 53 0.04 202 202 202 5.3 52 86 0.09 352 352 352

2.3 27 53 0.04 210 210 210 5.4 57 93 0.09 355 355 355

2.4 30 57 0.04 220 220 220 5.5 57 93 0.1 358 358 358

2.5 30 57 0.04 230 230 230 5.55 57 93 0.1 359 - - 359

2.6 30 57 0.04 240 240 240 5.6 57 93 0.1 361 361 361

2.65 30 57 0.04 - - 245 - - 5.7 57 93 0.1 364 364 364

2.7 33 61 0.04 250 250 250 5.8 57 93 0.1 367 367 367

2.8 33 61 0.04 260 260 260 5.9 57 93 0.1 369 369 369

2.9 33 61 0.04 270 270 270 6 57 93 0.11 371 371 371

3 33 61 0.04 280 280 280 6.1 63 101 0.11 373 373 373

3.1 36 65 0.04 282 282 282 6.2 63 101 0.11 375 375 375

3.2 36 65 0.04 286 286 286 6.3 63 101 0.11 377 377 377

3.25 36 65 0.05 287 287 287 6.35 63 101 0.11 378 378 - -

3.3 36 65 0.05 289 289 289 6.4 63 101 0.12 379 379 379

3.4 39 70 0.05 291 291 291 6.5 63 101 0.12 381 381 381

3.45 39 70 0.05 292 292 - - 6.6 63 101 0.12 383 383 383

3.5 39 70 0.05 293 293 293 6.7 63 101 0.12 385 385 385

3.6 39 70 0.05 296 296 296 6.8 69 109 0.12 387 387 387

3.7 39 70 0.06 299 299 299 6.9 69 109 0.13 389 389 389

3.8 43 75 0.06 302 302 302 7 69 109 0.13 391 391 391

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 66

0067_EN_2018_KERN[21841774]-n.indd 76 12/17/2018 3:31:54 PM