Page 67 - Icon Ridge Presents ATORN

P. 67

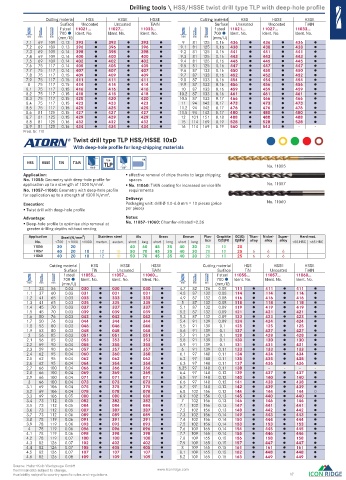

Drilling tools \ HSS/HSSE twist drill type TLP with deep-hole profi le

Cutting material HSS HSSE HSSE Cutting material HSS HSSE HSSE

Surface Uncoated Uncoated TiAlN Surface Uncoated Uncoated TiAlN

f steel 11021... 11027... 11033... f steel 11021... 11027... 11033...

700 Ident. No. Ident. No. Ident. No. 700 Ident. No. Ident. No. Ident. No.

mm mm mm (mm/U) mm mm mm (mm/U)

7.1 69 109 0.13 393 393 393 9 81 125 0.16 436 436 436

7.2 69 109 0.13 396 396 396 9.1 81 125 0.16 438 438 438

7.3 69 109 0.14 398 398 398 9.2 81 125 0.16 441 441 441

7.4 69 109 0.14 400 400 400 9.3 81 125 0.16 443 443 443

7.5 69 109 0.14 402 402 402 9.4 81 125 0.16 445 445 445

7.6 75 117 0.14 405 405 405 9.5 81 125 0.16 447 447 447

7.7 75 117 0.14 407 407 407 9.6 87 133 0.16 450 450 450

7.8 75 117 0.15 409 409 409 9.7 87 133 0.16 452 452 452

7.9 75 117 0.15 411 411 411 9.8 87 133 0.16 454 454 454

8 75 117 0.15 414 414 414 9.9 87 133 0.16 456 456 456

8.1 75 117 0.15 416 416 416 10 87 133 0.16 459 459 459

8.2 75 117 0.15 418 418 418 10.2 87 133 0.16 461 461 461

8.3 75 117 0.15 420 420 420 10.5 87 133 0.17 466 466 466

8.4 75 117 0.15 423 423 423 11 94 142 0.17 473 473 473

8.5 75 117 0.15 425 425 425 11.2 94 142 0.17 476 476 476

8.6 81 125 0.15 427 427 427 11.5 94 142 0.17 480 480 480

8.7 81 125 0.15 429 429 429 12 101 151 0.18 488 488 488

8.8 81 125 0.16 432 432 432 15 114 169 0.19 528 528 528

8.9 81 125 0.16 434 434 434 16 114 169 0.19 560 543 - -

Prod. Gr. 110

Twist drill type TLP HSS/HSSE 10xD

With deep-hole profi le for long-chipping materials

Typ HA

HSS HSSE TiN TiAlN TLP

10xD 130° No. 11055

Application: eff ective removal of chips thanks to large chipping

No. 11055: Geometry with deep-hole profi le for spaces

application up to a strength of 1000 N/mm . 2 No. 11060: TiAlN coating for increased service life No. 11057

No. 11057–11060: Geometry with deep-hole profi le requirements

for application up to a strength of 1300 N/mm . 2

Delivery:

Execution: Packaging unit: drill Ø 1.0-6.0 mm = 10 pieces (price No. 11060

Twist drill with deep-hole profi le per piece)

Advantage: Notes:

Deep-hole profi le to optimise chip removal at No. 11057–11060: Chamfer-nitrated >2.36

greater drilling depths without venting

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11055 30 20 40 60 45 35 40 30 20 10 20

11057 40 20 10 12 10 50 70 45 35 40 30 20 10 25 6 6 6

11060 40 20 10 12 10 50 70 45 35 40 30 20 10 25 6 6 6

Cutting material HSS HSSE HSSE Cutting material HSS HSSE HSSE

Surface TiN Uncoated TiAlN Surface TiN Uncoated TiAlN

f steel 11055... 11057... 11060... f steel 11055... 11057... 11060...

700 Ident. No. Ident. No. Ident. No. 700 Ident. No. Ident. No. Ident. No.

mm mm mm (mm/U) mm mm mm (mm/U)

1 33 56 0.03 030 030 030 4.7 82 126 0.08 111 411 411

1.1 37 60 0.03 031 031 031 4.8 87 132 0.08 114 114 114

1.2 41 65 0.03 033 333 333 4.9 87 132 0.08 116 416 416

1.3 41 65 0.03 035 335 335 5 87 132 0.08 118 118 118

1.4 45 70 0.03 037 337 337 5.1 87 132 0.09 119 419 419

1.5 45 70 0.03 039 039 039 5.2 87 132 0.09 121 421 421

1.6 50 76 0.03 042 042 042 5.3 87 132 0.09 123 423 423

1.7 50 76 0.03 044 344 344 5.4 91 139 0.09 124 424 424

1.8 53 80 0.03 046 046 046 5.5 91 139 0.1 125 125 125

1.9 53 80 0.03 048 048 048 5.6 91 139 0.1 127 427 427

2 56 85 0.03 051 051 051 5.7 91 139 0.1 128 428 428

2.1 56 85 0.03 053 353 353 5.8 91 139 0.1 130 130 130

2.2 59 90 0.04 055 355 355 5.9 91 139 0.1 131 431 431

2.3 59 90 0.04 057 357 357 6 91 139 0.11 133 133 133

2.4 62 95 0.04 060 360 360 6.1 97 148 0.11 134 434 434

2.5 62 95 0.04 062 062 062 6.2 97 148 0.11 135 435 435

2.6 62 95 0.04 064 364 364 6.3 97 148 0.11 137 436 436

2.7 66 100 0.04 066 366 366 6.35 97 148 0.11 138 - - - -

2.8 66 100 0.04 069 369 369 6.4 97 148 0.12 139 437 437

2.9 66 100 0.04 071 071 071 6.5 97 148 0.12 140 140 140

3 66 100 0.04 073 073 073 6.6 97 148 0.12 141 438 438

3.1 69 106 0.04 075 375 375 6.7 97 148 0.12 142 439 439

3.2 69 106 0.04 078 078 078 6.8 102 156 0.12 144 144 144 ○

3.3 69 106 0.05 080 080 080 6.9 102 156 0.13 145 440 440

3.4 73 112 0.05 082 382 382 7 102 156 0.13 146 146 146

3.5 73 112 0.05 084 084 084 7.1 102 156 0.13 147 441 441

3.6 73 112 0.05 087 387 387 7.2 102 156 0.13 148 442 442

3.7 73 112 0.06 089 089 089 7.3 102 156 0.14 149 443 443

3.8 78 119 0.06 091 391 391 7.4 102 156 0.14 150 444 444

3.9 78 119 0.06 093 093 093 7.5 102 156 0.14 153 153 153

4 78 119 0.06 096 096 096 7.6 109 165 0.14 154 445 445

4.1 78 119 0.06 098 398 398 7.7 109 165 0.14 155 446 446

4.2 78 119 0.07 100 100 100 7.8 109 165 0.15 156 158 158

4.3 82 126 0.07 102 402 402 7.9 109 165 0.15 157 447 447

4.4 82 126 0.07 105 405 405 8 109 165 0.15 161 161 161

4.5 82 126 0.07 107 107 107 8.1 109 165 0.15 162 448 448

4.6 82 126 0.08 109 109 109 8.2 109 165 0.15 163 449 449

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 67

0067_EN_2018_KERN[21841774]-n.indd 77 12/17/2018 3:31:56 PM