Page 73 - Icon Ridge Presents ATORN

P. 73

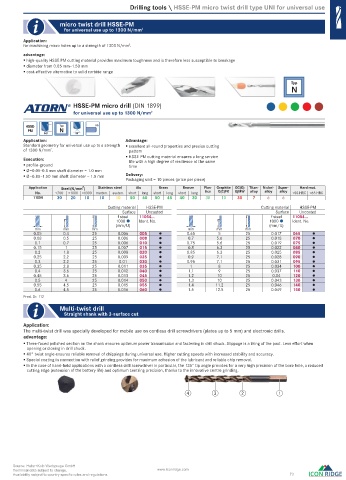

Drilling tools \ HSSE-PM micro twist drill type UNI for universal use

micro twist drill HSSE-PM

for universal use up to 1300 N/mm 2

Application:

for machining micro holes up to a strength of 1300 N/mm . 2

advantage:

high-quality HSSE PM cutting material provides maximum toughness and is therefore less susceptible to breakage

diameter from 0.05 mm–1.50 mm

cost-eff ective alternative to solid carbide range

Typ

N

HSSE-PM micro drill ( DIN 1899 )

for universal use up to 1300 N/mm 2

HSSE- Typ HA

PM N

5xD 118°

Application: Advantage:

Standard geometry for universal use up to a strength excellent all-round properties and precise cutting

of 1300 N/mm . 2 pattern

HSSE-PM cutting material ensures a long service

Execution: life with a high degree of resilience at the same

profi le-ground time

Ø=0.05-0.8 mm sha diameter = 1.0 mm

Ø=0.85–1.50 mm sha diameter = 1.5 mm Delivery:

Packaging unit = 10 pieces (price per piece)

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11054 30 20 10 10 10 50 60 50 45 40 30 30 10 30 7 6 6

Cutting material HSSE-PM Cutting material HSSE-PM

Surface Uncoated Surface Uncoated

f steel 11054... f steel 11054...

1000 Ident. No. 1000 Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

0.05 0.4 25 0.006 005 0.65 5 25 0.017 065

0.08 0.5 25 0.006 008 0.7 5.6 25 0.018 070

0.1 0.7 25 0.006 010 0.75 5.6 25 0.019 075

0.15 1 25 0.007 015 0.8 6.3 25 0.022 080

0.2 1.8 25 0.008 020 0.85 6.3 25 0.025 085

0.25 2.2 25 0.009 025 0.9 7.1 25 0.028 090

0.3 2.2 25 0.01 030 0.95 7.1 25 0.031 095

0.35 2.8 25 0.011 035 1 8 25 0.034 100

0.4 3.6 25 0.012 040 1.1 9 25 0.037 110

0.45 3.6 25 0.013 045 1.2 10 25 0.04 120

0.5 4 25 0.014 050 1.3 10 25 0.043 130

0.55 4.5 25 0.015 055 1.4 11.2 25 0.046 140

0.6 4.5 25 0.016 060 1.5 12.5 25 0.049 150

Prod. Gr. 112

Multi-twist drill

Straight shank with 3-surface cut

Application:

The multi-twist drill was specially developed for mobile use on cordless drill screwdrivers (plates up to 5 mm) and electronic drills.

advantage:

Three-faced polished section on the shank ensures optimum power transmission and fastening in drill chuck. Slippage is a thing of the past. Less eff ort when

opening or closing in drill chuck.

40° twist angle ensures reliable removal of chippings during universal use. Higher cutting speeds with increased stability and accuracy.

Special coating in connection with relief grinding provides for maximum adhesion of the lubricant and reliable chip removal.

In the case of hand-held applications with a cordless drill screwdriver in particular, the 135° tip angle provides for a very high precision of the bore hole, a reduced

cutting edge (extension of the battery life) and optimum centring precision, thanks to the innovative centre grinding.

4 3 2 1

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 73

0083_EN_2018_KERN[21841794]-l.indd 83 12/17/2018 3:31:05 PM