Page 91 - Icon Ridge Sanitary-Heating-Air Catalog

P. 91

Drilling, Milling, Tapping and Threading

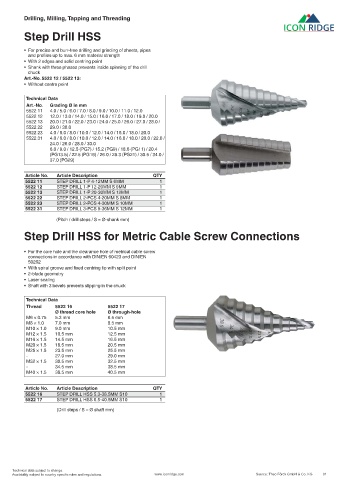

Step Drill HSS

• For precise and burr-free drilling and grinding of sheets, pipes

and profiles up to max. 6 mm material strength

• With 2 edges and solid centring point

• Shank with three phases prevents inside spinning of the drill

chuck

Art.-No. 5522 12 / 5522 13:

• Without centre point

Technical Data

Art.-No. Grading Ø in mm

5522 11 4.0 / 5.0 / 6.0 / 7.0 / 8.0 / 9.0 / 10.0 / 11.0 / 12.0

5522 12 12.0 / 13.0 / 14.0 / 15.0 / 16.0 / 17.0 / 18.0 / 19.0 / 20.0

5522 13 20.0 / 21.0 / 22.0 / 23.0 / 24.0 / 25.0 / 26.0 / 27.0 / 28.0 /

5522 22 29.0 / 30.0

5522 23 4.0 / 6.0 / 8.0 / 10.0 / 12.0 / 14.0 / 16.0 / 18.0 / 20.0

5522 31 4.0 / 6.0 / 8.0 / 10.0 / 12.0 / 14.0 / 16.0 / 18.0 / 20.0 / 22.0 /

24.0 / 26.0 / 28.0 / 30.0

6.0 / 9.0 / 12.5 (PG7) / 15.2 (PG9) / 18.6 (PG11) / 20.4

(PG13.5) / 22.5 (PG16) / 26.0 / 28.3 (PG21) / 30.5 / 34.0 /

37.0 (PG29)

Article No. Article Description QTY

5522 11 STEP DRILL 1-P 4-12MM S 6MM 1

5522 12 STEP DRILL 1-P 12-20MM S 9MM 1

5522 13 STEP DRILL 1-P 20-30MM S 12MM 1

5522 22 STEP DRILL 2-PCS 4-20MM S 8MM 1

5522 23 STEP DRILL 2-PCS 4-30MM S 10MM 1

5522 31 STEP DRILL 3-PCS 9-36MM S 12MM 1

(Pitch / drill steps / S = Ø-shank mm)

Step Drill HSS for Metric Cable Screw Connections

• For the core hole and the clearance hole of metrical cable screw

connections in accordance with DIN/EN 60423 and DIN/EN

50262

• With spiral groove and fixed centring tip with split point

• 2-blade geometry

• Laser scaling

• Shaft with 3 bevels prevents slipping in the chuck

Technical Data

Thread 5522 16 5522 17

Ø thread core hole Ø through-hole

M6 × 0.75 5.3 mm 6.5 mm

M8 × 1.0 7.0 mm 8.5 mm

M10 × 1.0 9.0 mm 10.5 mm

M12 × 1.5 10.5 mm 12.5 mm

M16 × 1.5 14.5 mm 16.5 mm

M20 × 1.5 18.5 mm 20.5 mm

M25 × 1.5 23.5 mm 25.5 mm

- 27.0 mm 29.0 mm

M32 × 1.5 30.5 mm 32.5 mm

- 34.5 mm 38.5 mm

M40 × 1.5 38.5 mm 40.5 mm

Article No. Article Description QTY

5522 16 STEP DRILL HSS 5.3-38.5MM S10 1

5522 17 STEP DRILL HSS 6.5-40.5MM S10 1

(Drill steps / S = Ø shaft mm)

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 91