Page 132 - Icon Ridge Presents ATORN

P. 132

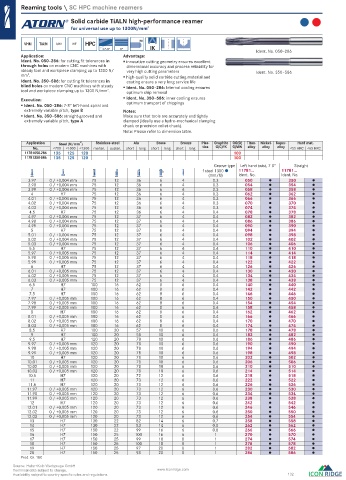

Reaming tools \ SC HPC machine reamers

Solid carbide TiALN high-performance reamer

for universal use up to 1300N/mm 2

VHM TiAlN 0,001 H7 HPC HA

7–8° 0° IK Ident. No. 050–286

Application: Advantage:

Ident. No. 050–286: for cutting fi t tolerances in innovative cutting geometry ensures excellent

through holes on modern CNC machines with dimensional accuracy and process reliability for

steady tool and workpiece clamping up to 1300 N/ very high cutting parameters Ident. No. 350–586

mm . 2 high-quality solid carbide cutting material and

Ident. No. 350–586: for cutting fi t tolerances in coating ensure a very long service life

blind holes on modern CNC machines with steady Ident. No. 050–286: Internal cooling ensures

tool and workpiece clamping up to 1300 N/mm . 2 optimum chip removal

Execution: Ident. No. 350–586: inner cooling ensures

Ident. No. 050–286: 7-8° left -hand spiral and optimum transport of chippings

extremely variable pitch, type B Notes:

Ident. No. 350–586: straight-grooved and Make sure that tools are accurately and tightly

extremely variable pitch, type A clamped (ideally use a hydro-mechanical clamping

chuck or precision collet chuck).

Note: Please refer to dimension table.

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11781050-286 135 125 120 100

11781350-586 135 125 120 100

Groove type Left -hand twist, 7-8° Straight

f steel 1300 11781... 11781...

h6

mm mm mm mm mm (mm/U) Ident. No. Ident. No.

3.97 0 / +0,004 mm 75 12 36 6 4 0.3 050 ● 350 ●

3.98 0 / +0,004 mm 75 12 36 6 4 0.3 054 ● 354 ●

3.99 0 / +0,004 mm 75 12 36 6 4 0.3 058 ● 358 ●

4 H7 75 12 36 6 4 0.3 062 ● 362 ●

4.01 0 / +0,004 mm 75 12 36 6 4 0.3 066 ● 366 ●

4.02 0 / +0,004 mm 75 12 36 6 4 0.3 070 ● 370 ●

4.03 0 / +0,004 mm 75 12 36 6 4 0.3 074 ● 374 ●

4.5 H7 75 12 36 6 4 0.4 078 ● 378 ●

4.97 0 / +0,004 mm 75 12 37 6 4 0.4 082 ● 382 ●

4.98 0 / +0,004 mm 75 12 37 6 4 0.4 086 ● 386 ●

4.99 0 / +0,004 mm 75 12 37 6 4 0.4 090 ● 390 ●

5 H7 75 12 37 6 4 0.4 094 ● 394 ●

5.01 0 / +0,004 mm 75 12 37 6 4 0.4 098 ● 398 ●

5.02 0 / +0,004 mm 75 12 37 6 4 0.4 102 ● 402 ●

5.03 0 / +0,004 mm 75 12 37 6 4 0.4 106 ● 406 ●

5.5 H7 75 12 37 6 4 0.4 110 ● 410 ●

5.97 0 / +0,005 mm 75 12 37 6 4 0.4 114 ● 414 ●

5.98 0 / +0,005 mm 75 12 37 6 4 0.4 118 ● 418 ●

5.99 0 / +0,005 mm 75 12 37 6 4 0.4 122 ● 422 ●

6 H7 75 12 37 6 4 0.4 126 ● 426 ●

6.01 0 / +0,005 mm 75 12 37 6 4 0.4 130 ● 430 ●

6.02 0 / +0,005 mm 75 12 37 6 4 0.4 134 ● 434 ●

6.03 0 / +0,005 mm 75 12 37 6 4 0.4 138 ● 438 ●

6.5 H7 100 16 62 8 6 0.4 140 ● 440 ●

7 H7 100 16 62 8 6 0.4 142 ● 442 ●

7.5 H7 100 16 62 8 6 0.4 146 ● 446 ●

7.97 0 / +0,005 mm 100 16 62 8 6 0.4 150 ● 450 ●

7.98 0 / +0,005 mm 100 16 62 8 6 0.4 154 ● 454 ●

7.99 0 / +0,005 mm 100 16 62 8 6 0.4 158 ● 458 ●

8 H7 100 16 62 8 6 0.4 162 ● 462 ●

8.01 0 / +0,005 mm 100 16 62 8 6 0.4 166 ● 466 ●

8.02 0 / +0,005 mm 100 16 62 8 6 0.4 170 ● 470 ●

8.03 0 / +0,005 mm 100 16 62 8 6 0.4 174 ● 474 ●

8.5 H7 100 20 57 10 6 0.6 178 ● 478 ●

9 H7 100 20 58 10 6 0.6 182 ● 482 ●

9.5 H7 120 20 78 10 6 0.6 186 ● 486 ●

9.97 0 / +0,005 mm 120 20 78 10 6 0.6 190 ● 490 ●

9.98 0 / +0,005 mm 120 20 78 10 6 0.6 194 ● 494 ●

9.99 0 / +0,005 mm 120 20 78 10 6 0.6 198 ● 498 ●

10 H7 120 20 78 10 6 0.6 202 ● 502 ●

10.01 0 / +0,005 mm 120 20 78 10 6 0.6 206 ● 506 ●

10.02 0 / +0,005 mm 120 20 78 10 6 0.6 210 ● 510 ●

10.03 0 / +0,005 mm 120 20 78 10 6 0.6 214 ● 514 ●

10.5 H7 120 20 72 12 6 0.6 218 ● 518 ●

11 H7 120 20 73 12 6 0.6 222 ● 522 ●

11.5 H7 120 20 73 12 6 0.6 226 ● 526 ●

11.97 0 / +0,005 mm 120 20 73 12 6 0.6 230 ● 530 ●

11.98 0 / +0,005 mm 120 20 73 12 6 0.6 234 ● 534 ●

11.99 0 / +0,005 mm 120 20 73 12 6 0.6 238 ● 538 ●

12 H7 120 20 73 12 6 0.6 242 ● 542 ●

12.01 0 / +0,005 mm 120 20 73 12 6 0.6 246 ● 546 ●

12.02 0 / +0,005 mm 120 20 73 12 6 0.6 250 ● 550 ●

12.03 0 / +0,005 mm 120 20 73 12 6 0.6 254 ● 554 ●

13 H7 130 22 82 14 6 0.7 258 ● 558 ●

14 H7 130 22 83 14 6 0.8 262 ● 562 ●

15 H7 150 22 99 16 6 0.8 266 ● 566 ●

16 H7 150 25 100 16 6 1 270 ● 570 ●

17 H7 150 25 99 18 8 1 274 ● 574 ●

18 H7 150 25 100 18 8 1 278 ● 578 ●

19 H7 150 25 97 20 8 1 282 ● 582 ●

20 H7 150 25 98 20 8 1 286 ● 586 ●

Prod. Gr. 1BK

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 132

0164_EN_2018_KERN[21846876]-h.indd 166 12/17/2018 3:31:10 PM