Page 133 - Icon Ridge Presents ATORN

P. 133

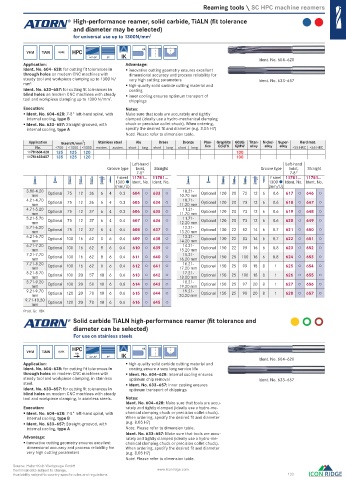

Reaming tools \ SC HPC machine reamers

High-performance reamer, solid carbide, TiALN (fi t tolerance

and diameter may be selected)

for universal use up to 1300N/mm 2

VHM TiAlN 0,00X HPC HA

7–8° 0° IK Ident. No. 604–628

Application: Advantage:

Ident. No. 604–628: for cutting fi t tolerances in innovative cutting geometry ensures excellent

through holes on modern CNC machines with dimensional accuracy and process reliability for

steady tool and workpiece clamping up to 1300 N/ very high cutting parameters Ident. No. 633–657

mm . 2 high-quality solid carbide cutting material and

Ident. No. 633–657: for cutting fi t tolerances in coating

blind holes on modern CNC machines with steady inner cooling ensures optimum transport of

tool and workpiece clamping up to 1300 N/mm . 2 chippings

Execution: Notes:

Ident. No. 604–628: 7-8° le -hand spiral, with Make sure that tools are accurately and tightly

internal cooling, type B clamped (ideally use a hydro-mechanical clamping

Ident. No. 633–657: Straight-grooved, with chuck or precision collet chuck). When ordering,

internal cooling, type A specify the desired fi t and diameter (e.g. 8.05 H7)

Note! Please refer to dimension table.

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11781604-628 135 125 120 100

11781633-657 135 125 120 100

Le -hand Le -hand

Groove type twist, Straight Groove type twist, Straight

7-8° 7-8°

f steel 11781... 11781... f steel 11781... 11781...

h6 h6

1300 Ident. No. Ident. No. 1300 Ident. No. Ident. No.

mm mm mm mm mm mm mm mm mm mm

(mm/U) (mm/U)

3.80-4.20 Optional 75 12 36 6 4 0.3 604 ○ 633 ○ 10.21- Optional 120 20 72 12 6 0.6 617 ○ 646 ○

mm 10.70 mm

4.21-4.70 Optional 75 12 36 6 4 0.3 605 ○ 634 ○ 10.71- Optional 120 20 73 12 6 0.6 618 ○ 647 ○

mm 11.20 mm

4.71-5.20 Optional 75 12 37 6 4 0.3 606 ○ 635 ○ 11.21- Optional 120 20 73 12 6 0.6 619 ○ 648 ○

mm 11.70 mm

5.21-5.70 Optional 75 12 37 6 4 0.4 607 ○ 636 ○ 11.71- Optional 120 20 73 12 6 0.6 620 ○ 649 ○

mm 12.20 mm

5.71-6.20 Optional 75 12 37 6 4 0.4 608 ○ 637 ○ 12.21- Optional 130 22 82 14 6 0.7 621 ○ 650 ○

mm 13.20 mm

6.21-6.70 Optional 100 16 62 8 6 0.4 609 ○ 638 ○ 13.21- Optional 130 22 83 14 6 0.7 622 ○ 651 ○

mm 14.20 mm

6.71-7.20 Optional 100 16 62 8 6 0.4 610 ○ 639 ○ 14.21- Optional 150 22 99 16 6 0.8 623 ○ 652 ○

mm 15.20 mm

7.21-7.70 Optional 100 16 62 8 6 0.4 611 ○ 640 ○ 15.21- Optional 150 25 100 16 6 0.8 624 ○ 653 ○

mm 16.20 mm

7.71-8.20 Optional 100 16 62 8 6 0.4 612 ○ 641 ○ 16.21- Optional 150 25 99 18 8 1 625 ○ 654 ○

mm 17.20 mm

8.21-8.70 Optional 100 20 57 10 6 0.6 613 ○ 642 ○ 17.21- Optional 150 25 100 18 8 1 626 ○ 655 ○

mm 18.20 mm

8.71-9.20 Optional 100 20 58 10 6 0.6 614 ○ 643 ○ 18.21- Optional 150 25 97 20 8 1 627 ○ 656 ○

mm 19.20 mm

9.21-9.70 Optional 120 20 78 10 6 0.6 615 ○ 644 ○ 19.21- Optional 150 25 98 20 8 1 628 ○ 657 ○

mm 20.20 mm

9.71-10.20 Optional 120 20 78 10 6 0.6 616 ○ 645 ○

mm

Prod. Gr. 1BK

Solid carbide TiALN high-performance reamer (fi t tolerance and

diameter can be selected)

For use on stainless steels

HPC HA

VHM TiAlN 0,00X VA

7–8° 0° IK Ident. No. 604–628

Application: high-quality solid carbide cutting material and

Ident. No. 604–628: for cutting fi t tolerances in coating ensure a very long service life

through holes on modern CNC machines with Ident. No. 604–628: Internal cooling ensures

steady tool and workpiece clamping, in stainless optimum chip removal Ident. No. 633–657

steel. Ident. No. 633–657: inner cooling ensures

Ident. No. 633–657: for cutting fi t tolerances in optimum transport of chippings

blind holes on modern CNC machines with steady

tool and workpiece clamping, in stainless steels. Notes:

Ident. No. 604–628: Make sure that tools are accu-

Execution: rately and tightly clamped (ideally use a hydro-me-

Ident. No. 604–628: 7-8° le -hand spiral, with chanical clamping chuck or precision collet chuck).

internal cooling, type B When ordering, specify the desired fi t and diameter

Ident. No. 633–657: Straight-grooved, with (e.g. 8.05 H7)

internal cooling, type A Note: Please refer to dimension table.

Ident. No. 633–657: Make sure that tools are accu-

Advantage: rately and tightly clamped (ideally use a hydro-me-

innovative cutting geometry ensures excellent chanical clamping chuck or precision collet chuck).

dimensional accuracy and process reliability for When ordering, specify the desired fi t and diameter

very high cutting parameters (e.g. 8.05 H7)

Note! Please refer to dimension table.

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 133

0167_EN_2018_KERN[21846882]-r.indd 167 12/17/2018 3:31:40 PM