Page 37 - Icon Ridge Presents ATORN

P. 37

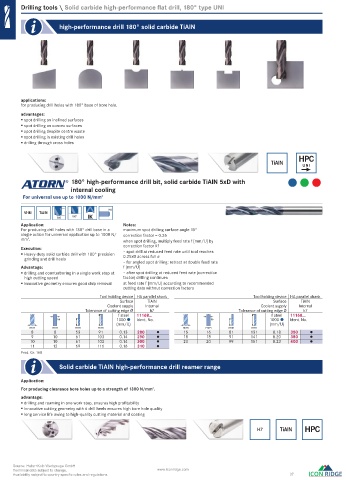

Drilling tools \ Solid carbide high-performance fl at drill, 180° type UNI

high-performance drill 180° solid carbide TiAlN

applications:

for producing drill holes with 180° base of bore hole.

advantages:

spot drilling on inclined surfaces

spot drilling on convex surfaces

spot drilling despite centre waste

spot drilling in existing drill holes

drilling through cross holes

HPC

TiAlN

UNI

180° high-performance drill bit, solid carbide TiAlN 5xD with

internal cooling

For universal use up to 1000 N/mm 2

HA

VHM TiAlN

5xD 180° IK

Application: Notes:

For producing drill holes with 180° drill base in a maximum spot drilling surface angle 15°

single action for universal application up to 1000 N/ correction factor = 0.25

mm . 2 when spot drilling, multiply feed rate f [mm/U] by

Execution: correction factor Kf

Heavy-duty solid carbide drill with 180° precision – spot drill at reduced feed rate until tool reaches

0.25xD across full ø

grinding and drill heels – for angled spot drilling: retract at double feed rate

Advantage: f [mm/U]

drilling and counterboring in a single work step at – a er spot drilling at reduced feed rate (correction

high cutting speed factor) drilling continues

Innovative geometry ensures good chip removal at feed rate f [mm/U] according to recommended

cutting data without correction factors

Tool holding device HA parallel shank Tool holding device HA parallel shank

Surface TiAlN Surface TiAlN

Coolant supply Internal Coolant supply Internal

Tolerance of cutting edge Ø h7 Tolerance of cutting edge Ø h7

f steel 11168... f steel 11168...

h6 1000 Ident. No. h6 1000 Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

8 8 53 91 0.13 280 15 16 81 131 0.18 350

9 10 61 103 0.14 290 18 18 91 141 0.20 380

10 10 61 103 0.14 300 20 20 99 151 0.23 400

11 12 69 116 0.16 310

Prod. Gr. 1AB

Solid carbide TiAlN high-performance drill reamer range

Application:

For producing clearance bore holes up to a strength of 1300 N/mm . 2

advantage:

drilling and reaming in one work step, ensures high profi tability

innovative cutting geometry with 6 drill heels ensures high bore hole quality

long service life owing to high-quality cutting material and coating

H7 TiAlN HPC

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 37

0045_EN_2018_KERN[21841708]-m.indd 46 12/17/2018 3:31:11 PM