Page 41 - Icon Ridge Presents ATORN

P. 41

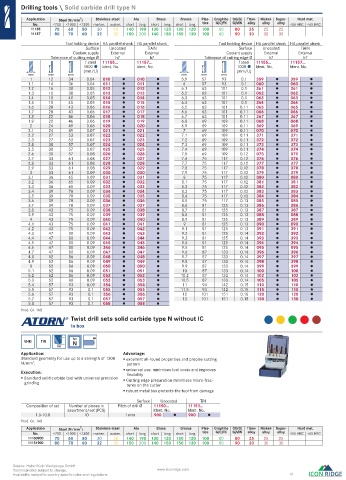

Drilling tools \ Solid carbide drill type N

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11155 70 60 50 30 28 140 190 130 120 130 120 100 80 80 25 25 25

11157 80 70 60 32 30 150 200 140 150 150 130 100 80 90 30 30 30

Tool holding device HA parallel shank HA parallel shank Tool holding device HA parallel shank HA parallel shank

Surface Uncoated TiAlN Surface Uncoated TiAlN

Coolant supply External External Coolant supply External External

Tolerance of cutting edge Ø h7 h7 Tolerance of cutting edge Ø h7 h7

f steel 11155... 11157... f steel 11155... 11157...

1000 Ident. No. Ident. No. 1000 Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

1 12 34 0.04 010 010 5.9 57 93 0.1 359 359

1.1 14 36 0.04 011 011 6 57 93 0.1 060 060

1.2 16 38 0.05 012 012 6.1 63 101 0.1 361 361

1.3 16 38 0.05 013 013 6.2 63 101 0.1 062 062

1.4 18 40 0.05 014 014 6.3 63 101 0.1 063 063

1.5 18 40 0.05 015 015 6.4 63 101 0.1 364 364

1.6 20 43 0.06 016 016 6.5 63 101 0.11 065 065

1.7 20 43 0.06 017 017 6.6 63 101 0.11 066 066

1.8 22 46 0.06 018 018 6.7 63 101 0.11 367 367

1.9 22 46 0.06 019 019 6.8 69 109 0.11 068 068

2 24 49 0.06 020 020 6.9 69 109 0.11 369 369

2.1 24 49 0.07 021 021 7 69 109 0.11 070 070

2.2 27 53 0.07 022 022 7.1 69 109 0.11 371 371

2.3 27 53 0.07 023 023 7.2 69 109 0.11 372 372

2.4 30 57 0.07 024 024 7.3 69 109 0.11 373 373

2.5 30 57 0.07 025 025 7.4 69 109 0.11 374 374

2.6 30 57 0.08 026 026 7.5 69 109 0.12 075 075

2.7 33 61 0.08 027 027 7.6 75 117 0.12 376 376

2.8 33 61 0.08 028 028 7.7 75 117 0.12 377 377

2.9 33 61 0.08 029 029 7.8 75 117 0.12 378 378

3 33 61 0.09 030 030 7.9 75 117 0.12 379 379

3.1 36 65 0.09 031 031 8 75 117 0.12 080 080

3.2 36 65 0.09 032 032 8.1 75 117 0.12 381 381

3.3 36 65 0.09 033 033 8.2 75 117 0.12 382 382

3.4 39 70 0.09 034 034 8.3 75 117 0.12 383 383

3.5 39 70 0.09 035 035 8.4 75 117 0.13 384 384

3.6 39 70 0.09 036 036 8.5 75 117 0.13 085 085

3.7 39 70 0.09 037 037 8.6 81 125 0.13 386 386

3.8 43 75 0.09 038 038 8.7 81 125 0.13 387 387

3.9 43 75 0.09 039 039 8.8 81 125 0.13 088 088

4 43 75 0.09 040 040 8.9 81 125 0.13 389 389

4.1 43 75 0.09 041 041 9 81 125 0.13 090 090

4.2 43 75 0.09 042 042 9.1 81 125 0.13 391 391

4.3 47 80 0.09 043 043 9.2 81 125 0.14 392 392

4.4 47 80 0.09 044 344 9.3 81 125 0.14 393 393

4.5 47 80 0.09 045 045 9.4 81 125 0.14 394 394

4.6 47 80 0.09 346 346 9.5 81 125 0.14 095 095

4.7 47 80 0.09 047 047 9.6 87 133 0.14 396 396

4.8 52 86 0.09 048 048 9.7 87 133 0.14 397 397

4.9 52 86 0.09 049 049 9.8 87 133 0.14 398 398

5 52 86 0.09 050 050 9.9 87 133 0.14 399 399

5.1 52 86 0.09 051 051 10 87 133 0.14 100 100

5.2 52 86 0.09 052 052 10.2 87 133 0.14 102 102

5.3 52 86 0.09 053 053 10.5 87 133 0.14 105 105

5.4 57 93 0.09 354 354 11 94 142 0.15 110 110

5.5 57 93 0.1 055 055 11.5 94 142 0.15 115 115

5.6 57 93 0.1 356 356 12 101 151 0.18 120 120

5.7 57 93 0.1 057 057 13 101 151 0.18 130 130

5.8 57 93 0.1 058 058

Prod. Gr. 1AB

Twist drill sets solid carbide type N without IC

In box

Typ HA

VHM TiN N

3xD

Application: Advantage:

Standard geometry for use up to a strength of 1300 excellent all-round properties and precise cutting

N/mm . 2 pattern

Execution: universal use: minimises tool costs and improves

fl exibility

Standard solid carbide tool with universal precision Cutting edge preparation minimises micro-frac-

grinding tures on the cutter

robust metal box protects the tool from damage

Surface Uncoated TiN

Composition of set Number of pieces in Pitch of drill Ø 11150... 11151...

assortment/set (PCS) Ident. No. Ident. No.

1.0-10.0 10 1 mm 900 900

Prod. Gr. 1AB

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11150900 70 60 50 30 28 140 190 130 120 130 120 100 80 80 25 25 25

11151900 80 70 60 32 30 150 200 140 150 150 130 100 80 90 30 30 30

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 41

0047_EN_2018_KERN[21841715]-k.indd 50 12/17/2018 3:31:14 PM