Page 174 - Icon Ridge Presents ORION

P. 174

Milling tools monoblock \ Technical introduction – monobloc milling

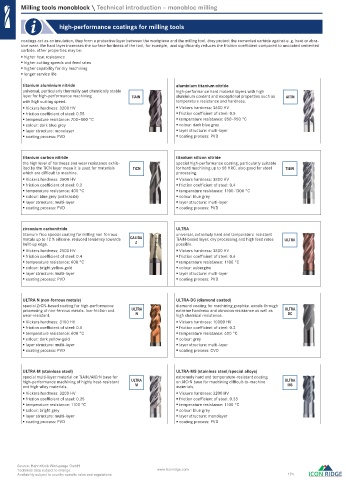

high-performance coatings for milling tools

coatings act as an insulation, they form a protective layer between the workpiece and the milling tool. they protect the cemented carbide against e. g. heat or abra-

sive wear. the hard layer increases the surface hardness of the tool, for example, and signifi cantly reduces the friction coeffi cient compared to uncoated cemented

carbide. other properties may be:

higher heat resistance

higher cutting speeds and feed rates

higher capability for dry machining

longer service life

titanium aluminium nitride aluminium titanium nitride

universal, particularly thermally and chemically stable high-performance hard material layers with high

layer for high-performance machining TiAlN aluminium content and exceptional properties such as AlTiN

with high cutting speed. temperature resistance and hardness.

Vickers hardness: 3200 HV Vickers hardness: 3600 HV

friction coeffi cient of steel: 0.55 friction coeffi cient of steel: 0.5

temperature resistance: 700–800 °C temperature resistance: 850–950 °C

colour: dark blue grey colour: dark blue grey

layer structure: monolayer layer structure: multi-layer

coating process: PVD coating process: PVD

titanium carbon nitride titanium silicon nitride

the high level of hardness and wear resistance exhib- special high-performance coating, particularly suitable

ited by the TiCN layer mean it is used for materials TiCN for hard machining up to 68 HRC. also good for steel TiSiN

which are diffi cult to machine. processing.

Vickers hardness: 3500 HV Vickers hardness: 3800 HV

friction coeffi cient of steel: 0.2 friction coeffi cient of steel: 0.4

temperature resistance: 400 °C temperature resistance: 1100-1300 °C

colour: blue grey (anthracite) colour: blue grey

layer structure: multi-layer layer structure: multi-layer

coating process: PVD coating process: PVD

zirconium carbonitride ULTRA

titanium-free special coating for milling non-ferrous universal, extremely hard and temperature-resistant

metals up to 12 % silicone. reduced tendency towards CALIDA TiAlN-based layer. dry processing and high feed rates ULTRA

built-up edge. Z possible.

Vickers hardness: 2500 HV Vickers hardness: 3800 HV

friction coeffi cient of steel: 0.4 friction coeffi cient of steel: 0.6

temperature resistance: 600 °C temperature resistance: 1100 °C

colour: bright yellow-gold colour: aubergine

layer structure: multi-layer layer structure: multi-layer

coating process: PVD coating process: PVD

ULTRA N (non-ferrous metals) ULTRA-DC (diamond coated)

special ZrCN-based coating for high-performance diamond coating for machining graphite. excels through

processing of non-ferrous metals. low-friction and ULTRA extreme hardness and abrasion resistance as well as ULTRA

wear-resistant. N high chemical resistance. DC

Vickers hardness: 3100 HV Vickers hardness: 10000 HV

friction coeffi cient of steel: 0.5 friction coeffi cient of steel: 0.2

temperature resistance: 600 °C temperature resistance: 600 °C

colour: dark yellow-gold colour: grey

layer structure: multi-layer layer structure: multi-layer

coating process: PVD coating process: CVD

ULTRA-M (stainless steel) ULTRA-MS (stainless steel/special alloys)

special multi-layer material on TiAlN/AlCrN base for extremely hard and temperature-resistant coating

high-performance machining of highly heat-resistant ULTRA on AlCrN base for machining diffi cult-to-machine ULTRA

and high-alloy materials. M materials. MS

Vickers hardness: 3200 HV Vickers hardness: 3200 HV

friction coeffi cient of steel: 0.35 friction coeffi cient of steel: 0.35

temperature resistance: 1100 °C temperature resistance: 1100 °C

colour: bright grey colour: blue grey

layer structure: multi-layer layer structure: monolayer

coating process: PVD coating process: PVD

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 174

0340_EN_2018_KERN[21847562]-g.indd 340 12/17/2018 3:32:26 PM