Page 15 - Industrial Tools Catalog (2)

P. 15

Workpiece clamping \ Lathe chucks and accessories

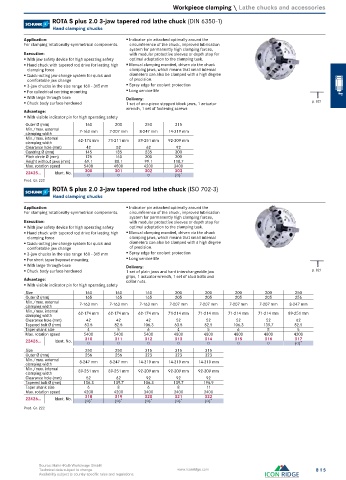

ROTA S plus 2.0 3-jaw tapered rod lathe chuck (DIN 6350-1)

Hand clamping chucks

Application: Indicator pin attached optimally around the

For clamping rotationally-symmetrical components. circumference of the chuck, improved lubrication

system for permanently high clamping forces,

Execution: with modular protective sleeves or depth stop for

With jaw safety device for high operating safety optimal adaptation to the clamping task.

Hand chuck with tapered rod drive for lasting high Manual clamping mandrel, driven via the chuck

clamping force clamping jaws, which means that small internal

Quick-acting jaw change system for quick and diameters can also be clamped with a high degree

comfortable jaw change of precision.

3-jaw chucks in the size range 160 - 315 mm Spray edge for coolant protection

For cylindrical centring mounting Long service life

With large through-bore Delivery:

Chuck body surface hardened 1 set of one-piece stepped block jaws, 1 actuator p. 821

Advantage: wrench, 1 set of fastening screws

With visible indicator pin for high operating safety

Outer Ø (mm) 160 200 250 315

Min./max. external 7-163 mm 7-207 mm 8-247 mm 14-319 mm

clamping width

Min./max. internal 62-174 mm 71-211 mm 89-251 mm 92-309 mm

clamping width

Clearance hole (mm) 42 52 62 92

Centring Ø (mm) 145 185 235 300

Pitch circle Ø (mm) 125 160 200 200

Height without jaws (mm) 69.1 88.1 99.1 118.7

Max. rotation speed 5400 4800 4200 3400

22425... Ident. No. 300 301 302 303 +

○

○

(○)

○

Prod. Gr. 222

ROTA S plus 2.0 3-jaw tapered rod lathe chuck (ISO 702-3)

Hand clamping chucks

Application: Indicator pin attached optimally around the

For clamping rotationally-symmetrical components. circumference of the chuck, improved lubrication

system for permanently high clamping forces,

Execution: with modular protective sleeves or depth stop for

With jaw safety device for high operating safety optimal adaptation to the clamping task.

Hand chuck with tapered rod drive for lasting high Manual clamping mandrel, driven via the chuck

clamping force clamping jaws, which means that small internal

Quick-acting jaw change system for quick and diameters can also be clamped with a high degree

comfortable jaw change of precision.

3-jaw chucks in the size range 160 - 315 mm Spray edge for coolant protection

For short taper bayonet mounting Long service life

With large through-bore Delivery:

Chuck body surface hardened 1 set of plain jaws and hard interchangeable jaw p. 821

Advantage: grips, 1 actuator wrench, 1 set of stud bolts and

collar nuts.

With visible indicator pin for high operating safety

Size 160 160 160 200 200 200 200 250

Outer Ø (mm) 165 165 165 205 205 205 205 256

Min./max. external

clamping width 7-163 mm 7-163 mm 7-163 mm 7-207 mm 7-207 mm 7-207 mm 7-207 mm 8-247 mm

Min./max. internal

clamping width 62-174 mm 62-174 mm 62-174 mm 71-214 mm 71-214 mm 71-214 mm 71-214 mm 89-251 mm

Clearance hole (mm) 42 42 42 52 52 52 52 62

Tapered bolt Ø (mm) 63.5 82.5 106.3 63.5 82.5 106.3 139.7 82.5

Taper shank size 4 5 6 4 5 6 8 5

Max. rotation speed 5400 5400 5400 4800 4800 4800 4800 4200

22426... Ident. No. 310 311 312 313 314 315 316 317 +

○

○

○

○

○

○

○

(○)

Size 250 250 315 315 315

Outer Ø (mm) 256 256 323 323 323

Min./max. external 8-247 mm 8-247 mm 14-319 mm 14-319 mm 14-319 mm

clamping width

Min./max. internal 89-251 mm 89-251 mm 92-309 mm 92-309 mm 92-309 mm

clamping width

Clearance hole (mm) 52 62 92 92 92

Tapered bolt Ø (mm) 106.3 139.7 106.3 139.7 196.9

Taper shank size 6 8 6 8 11

Max. rotation speed 4200 4200 3400 3400 3400

22426... Ident. No. 318 + 319 + 320 + 321 + 322 +

(○)

(○)

(○)

(○)

(○)

Prod. Gr. 222

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 815

Availability subject to country specific rules and regulations.