Page 27 - Industrial Tools Catalog (2)

P. 27

Magnetic clamping technology \ Permanent magnetic clamping plates

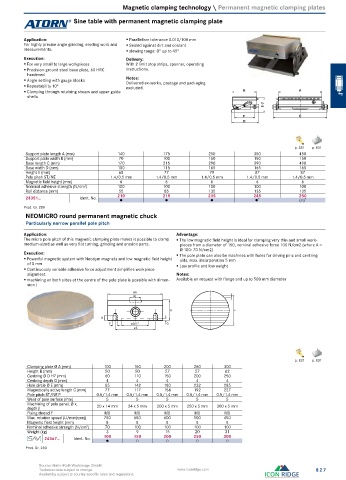

Sine table with permanent magnetic clamping plate

Application: Parallelism tolerance 0.010/100 mm

For highly precise angle grinding, eroding work and Sealed against dirt and coolant

measurements. slewing range: 0° up to 45°

Execution: Delivery:

For very small to large workpieces With 2 limit stop strips, spanner, operating

Precision-ground steel base plate, 60 HRC instructions.

hardened

Angle setting with gauge blocks Notes:

Delivered ex-works, postage and packaging

Repeatability 10“ excluded.

Clamping through retaining shears and upper guide

shells

p. 831 p. 831

Support plate length A (mm) 140 175 250 350 450

Support plate width B (mm) 70 100 150 150 150

Base length C (mm) 170 215 290 390 490

Base width D (mm) 100 115 165 165 165

Height E (mm) 68 77 79 87 87

Pole pitch ST/NE 1.4/0.5 mm 1.4/0.5 mm 1.4/0.5 mm 1.4/0.5 mm 1.4/0.5 mm

Magnetic field height (mm) 6 6 6 6 6

Nominal adhesive strength (N/cm ) 2 100 100 100 100 100

Roll distance (mm) 55 85 135 135 135

24351... Ident. No. 210 215 235 245 250 +

+

(○)

●

●

●

●

Prod. Gr. 280

NEOMICRO round permanent magnetic chuck

Particularly narrow parallel pole pitch

Application: Advantage:

The micro pole pitch of this magnetic clamping plate makes it possible to clamp The low magnetic field height is ideal for clamping very thin and small work-

medium-sized as well as very flat turning, grinding and erosion parts. pieces from a diameter of 150, nominal adhesive force 100 N/cm2 (where A =

Ø 100: 70 N/cm2)

Execution: The pole plate can also be machines with holes for driving pins and centring

Powerful magnetic system with Neodym magnets and low magnetic field height aids, max. incorporation 5 mm

of 8 mm Low profile and low weight

Continuously variable adhesive force adjustment simplifies workpiece

alignment Notes:

machining on both sides at the centre of the pole plate is possible with dimen- Available on request with flange and up to 500 mm diameter

sion J

A

J P

B C

H

F D H7 G

E

p. 831 p. 831

Clamping plate Ø A (mm) 100 150 200 250 300

Height B (mm) 50 50 57 57 62

Centring Ø D H7 (mm) 60 110 150 200 250

Centring depth G (mm) 4 4 4 4 4

Hole circle Ø E (mm) 85 142 180 232 285

Magnetically active length C (mm) 77 117 154 192 227

Pole pitch ST/NE P 0.5/1.4 mm 0.5/1.4 mm 0.5/1.4 mm 0.5/1.4 mm 0.5/1.4 mm

Wear of pole surface (mm) 5 5 5 5 5

Machining of pole panel, Ø x, 20 x 14 mm 24 x 5 mm 200 x 5 mm 250 x 5 mm 300 x 5 mm

depth J

Fixing thread F M8 M8 M8 M8 M8

Max. rotation speed (U/min(rpm)) 780 680 600 500 450

Magnetic field height (mm) 8 8 8 8 8

Nominal adhesive strength (N/cm ) 2 70 100 100 100 100

Weight (kg) 3 9 15 20 31

24367... Ident. No. 100 150 200 250 300

○

●

○

○

○

Prod. Gr. 230

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 827

Availability subject to country specific rules and regulations.