Page 137 - 2022FittingsCatalog

P. 137

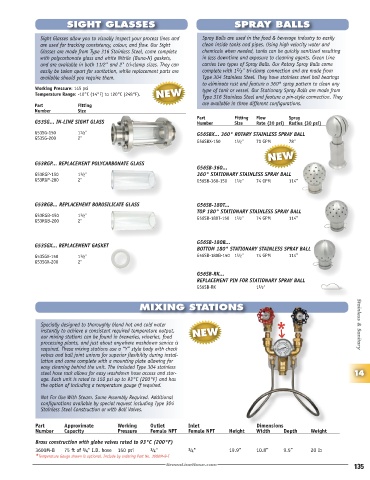

SIGHT GLASSES SPRAY BALLS

Sight Glasses allow you to visually inspect your process lines and Spray Balls are used in the food & beverage industry to easily

are used for tracking consistency, colour, and flow. Our Sight clean inside tanks and pipes. Using high velocity water and

Glasses are made from Type 316 Stainless Steel, come complete chemicals when needed, tanks can be quickly sanitized resulting

with polycarbonate glass and white Nitrile (Buna-N) gaskets, in less downtime and exposure to cleaning agents. Green Line

and are available in both 11⁄2" and 2" tri-clamp sizes. They can carries two types of Spray Balls. Our Rotary Spray Balls come

1

easily be taken apart for sanitation, while replacement parts are complete with 1 ⁄ " tri-clamp connection and are made from

2

available should you require them. Type 304 Stainless Steel. They have stainless steel ball bearings

to eliminate rust and feature a 360° spray pattern to clean any

Working Pressure: 145 psi type of tank or vessel. Our Stationary Spray Balls are made from

Temperature Range: -10°C (14°F) to 120°C (248°F).

Type 316 Stainless Steel and feature a pin-style connection. They

Part Fitting are available in three different configurations.

Number Size

Part Fitting Flow Spray

G53SG... IN-LINE SIGHT GLASS Number Size Rate (30 psi) Radius (30 psi)

G53SG-150 1 1 ⁄2" G56SBX... 360° ROTARY STAINLESS SPRAY BALL

G53SG-200 2"

G56SBX-150 1 1 ⁄2" 70 GPM 78"

G53RGP... REPLACEMENT POLYCARBONATE GLASS

G56SB-360...

G53RGP-150 1 1 ⁄2" 360° STATIONARY STAINLESS SPRAY BALL

G53RGP-200 2" G56SB-360-150 1 1 ⁄2" 74 GPM 114"

G53RGB... REPLACEMENT BOROSILICATE GLASS G56SB-180T...

TOP 180° STATIONARY STAINLESS SPRAY BALL

G53RGB-150 1 1 ⁄2" G56SB-180T-150 1 1 ⁄2" 74 GPM 114"

G53RGB-200 2"

G56SB-180B...

G53SGX... REPLACEMENT GASKET

BOTTOM 180° STATIONARY STAINLESS SPRAY BALL

G53SGX-150 1 1 ⁄2" G56SB-180B-150 1 1 ⁄2" 74 GPM 114"

G53SGX-200 2"

G56SB-RK...

REPLACEMENT PIN FOR STATIONARY SPRAY BALL

G56SB-RK 1 1 ⁄2"

MIXING STATIONS

Specially designed to thoroughly blend hot and cold water Stainless & Sanitary

instantly to achieve a consistent required temperature output,

our mixing stations can be found in breweries, wineries, food

processing plants, and just about anywhere washdown service is

required. These mixing stations use a “Y” style body with check

valves and ball joint unions for superior flexibility during instal-

lation and come complete with a mounting plate allowing for

easy cleaning behind the unit. The included Type 304 stainless

steel hose rack allows for easy washdown hose access and stor- 14

age. Each unit is rated to 150 psi up to 93°C (200°F) and has

the option of including a temperature gauge if required.

Not For Use With Steam. Some Assembly Required. Additional

configurations available by special request including Type 304

Stainless Steel Construction or with Ball Valves.

Part Approximate Working Outlet Inlet Dimensions

Number Capacity Pressure Female NPT Female NPT Height Width Depth Weight

Brass construction with globe valves rated to 93°C (200°F)

3600M-B 75 ft of 3 ⁄4" I.D. hose 150 psi 3 ⁄4" 3 ⁄4" 19.9” 10.8” 9.5” 20 lb

*Temperature Gauge shown is optional. Include by ordering Part No. 3600M-B-T

135