Page 2 - P S - ECS MLY

P. 2

Infrastructure available:

1. Inspection Shed:- 03 pit lines and 04 catwalk arrangement with an overall length of

288.10mts/pitline, to undertake Trip/IA/IC schedules of EMU & MEMU Rakes of 12-

Car.

2. POH/ Heavy Repair Shed:- 03 repair bays (HL, ML & LL) with an overall size of 150

x 48 mts to undertake Heavy repair / POH schedule and other major unscheduled

attentions.

3. Washing Lines:-02 washing lines with catwalk arrangement for washing of EMU &

MEMU rakes of 9 car rake formation. Extension facility for 12- Car rake is under

process.

4. Stabling Lines:-03 stabling lines are available to stable EMU/MEMU rakes of 16

car length. These lines are used to stable any empty/spare rake .

5. Pit wheel lathe:- 01 No of conventional type Pit wheel lathe of M/s HYT make is

available. Any irregularity in wheel Dia or profile will be rectified in the pit wheel lathe

shed.

6. Oil filtration plant: 01 No oil filtration plant of M/s CEE DEE Make is available for

Filtration of transformer oil of EMU/MEMU coaches.

8. AMM Stores depot:-Stores depot available for procurement and storage of Stock

(Regular consumables) / Non-stock items.

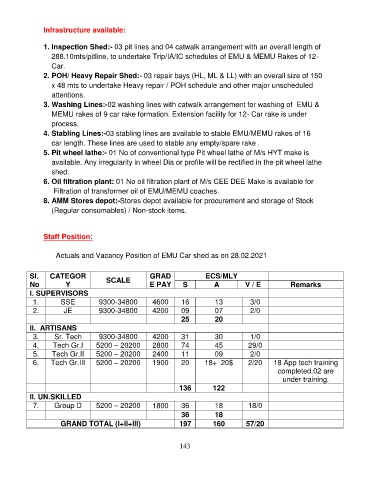

Staff Position:

Actuals and Vacancy Position of EMU Car shed as on 28.02.2021

Sl. CATEGOR GRAD ECS/MLY

No Y SCALE E PAY S A V / E Remarks

I. SUPERVISORS

1. SSE 9300-34800 4600 16 13 3/0

2. JE 9300-34800 4200 09 07 2/0

25 20

II. ARTISANS

3. Sr. Tech 9300-34800 4200 31 30 1/0

4. Tech Gr.I 5200 – 20200 2800 74 45 29/0

5. Tech Gr.II 5200 – 20200 2400 11 09 2/0

6. Tech Gr.III 5200 – 20200 1900 20 18+ 20$ 2/20 18 App tech training

completed.02 are

under training.

136 122

II. UN.SKILLED

7. Group D 5200 – 20200 1800 36 18 18/0

36 18

GRAND TOTAL (I+II+III) 197 160 57/20

143