Page 16 - Mountain Transport - RO-RO Lorry Operations

P. 16

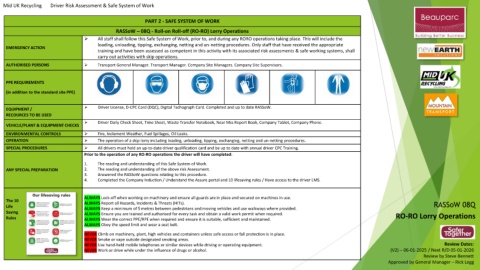

Mid UK Recycling Driver Risk Assessment & Safe System of Work

PART 2 - SAFE SYSTEM OF WORK

RASSoW – 08Q - Roll-on Roll-off (RO-RO) Lorry Operations

All staff shall follow this Safe System of Work, prior to, and during any RORO operations taking place. This will include the

loading, unloading, tipping, exchanging, netting and un-netting procedures. Only staff that have received the appropriate

EMERGENCY ACTION

training and have been assessed as competent in this activity with its associated risk assessments & safe working systems, shall

carry out activities with skip operations.

AUTHORISED PERSONS Transport General Manager. Transport Manager. Company Site Managers. Company Site Supervisors.

PPE REQUIREMENTS

☒ ☒ ☒ ☒ ☐ ☐

(in addition to the standard site PPE)

Driver License, D-CPC Card (DQC), Digital Tachograph Card. Completed and up to date RASSoW.

EQUIPMENT /

RECOURCES TO BE USED

Driver Daily Check Sheet, Time Sheet, Waste Transfer Notebook, Near Mss Report Book, Company Tablet, Company Phone.

VEHICLE/PLANT & EQUIPMENT CHECKS

ENVIRONMENTAL CONTROLS Fire, Inclement Weather, Fuel Spillages, Oil Leaks.

OPERATION The operation of a skip lorry including loading, unloading, tipping, exchanging, netting and un-netting procedures.

SPECIAL PROCEDURES All drivers must hold an up-to-date driver qualification card and be up to date with annual driver CPC Training.

Prior to the operation of any RO-RO operations the driver will have completed:

1. The reading and understanding of this Safe System of Work.

ANY SPECIAL PREPARATION 2. The reading and understanding of the above risk Assessment.

3. Answered the RASSoW questions relating to this procedure.

4. Completed the Company Induction / Understand the Assure portal and 10 lifesaving rules / Have access to the driver LMS.

ALWAYS Lock-off when working on machinery and ensure all guards are in place and secured on machines in use.

The 10

ALWAYS Report all Hazards, Incidents & Threats (HITs). RASSoW 08Q

Life

ALWAYS Keep a minimum of 5 metres between pedestrians and moving vehicles and use walkways where provided.

Saving

ALWAYS Ensure you are trained and authorised for every task and obtain a valid work permit when required. RO-RO Lorry Operations

Rules ALWAYS Wear the correct PPE/RPE when required and ensure it is suitable, sufficient and maintained.

ALWAYS Obey the speed limit and wear a seat belt.

NEVER Climb on machinery, plant, high vehicles and containers unless safe access or fall protection is in place.

NEVER Smoke or vape outside designated smoking areas.

NEVER Use hand-held mobile telephones or similar devices while driving or operating equipment. Review Dates:

NEVER Work or drive while under the influence of drugs or alcohol. (V2) – 06-01-2025 / Next R/D 05-01-2026

Review by Steve Bennett

Approved by General Manager – Rick Legg