Page 4 - GMP for warehouse

P. 4

GMP Training – GMP for Warehouse by www.gmpsop.com

Examples of government audit findings for warehouses

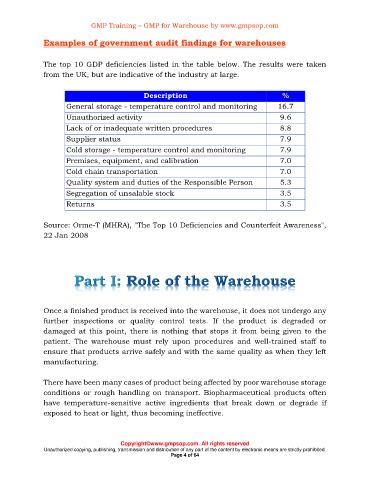

The top 10 GDP deficiencies listed in the table below. The results were taken

from the UK, but are indicative of the industry at large.

Description %

General storage - temperature control and monitoring 16.7

Unauthorized activity 9.6

Lack of or inadequate written procedures 8.8

Supplier status 7.9

Cold storage - temperature control and monitoring 7.9

Premises, equipment, and calibration 7.0

Cold chain transportation 7.0

Quality system and duties of the Responsible Person 5.3

Segregation of unsalable stock 3.5

Returns 3.5

Source: Orme-T (MHRA), "The Top 10 Deficiencies and Counterfeit Awareness",

22 Jan 2008

Once a finished product is received into the warehouse, it does not undergo any

further inspections or quality control tests. If the product is degraded or

damaged at this point, there is nothing that stops it from being given to the

patient. The warehouse must rely upon procedures and well-trained staff to

ensure that products arrive safely and with the same quality as when they left

manufacturing.

There have been many cases of product being affected by poor warehouse storage

conditions or rough handling on transport. Biopharmaceutical products often

have temperature-sensitive active ingredients that break down or degrade if

exposed to heat or light, thus becoming ineffective.

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic means are strictly prohibited.

Page 4 of 64