Page 34 - QA and QC

P. 34

GMP Training – Quality Assurance and Quality Control by www.gmpsop.com

GMP and process control

Under GMP, all manufacturing process steps must be "under control". After

processes are initially validated, to maintain control:

Inputs (CPPs or critical processing parameters) should be monitored

throughout the process.

Outputs (CQAs or critical quality attributes) should also be monitored against

tolerances.

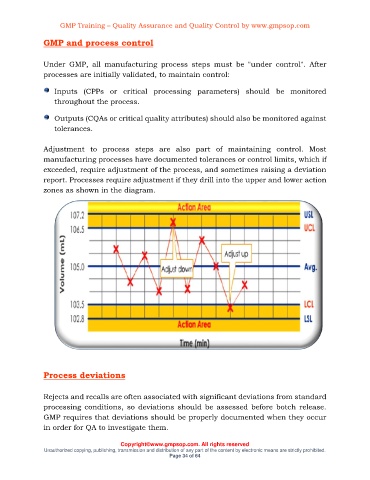

Adjustment to process steps are also part of maintaining control. Most

manufacturing processes have documented tolerances or control limits, which if

exceeded, require adjustment of the process, and sometimes raising a deviation

report. Processes require adjustment if they drill into the upper and lower action

zones as shown in the diagram.

Process deviations

Rejects and recalls are often associated with significant deviations from standard

processing conditions, so deviations should be assessed before botch release.

GMP requires that deviations should be properly documented when they occur

in order for QA to investigate them.

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic means are strictly prohibited.

Page 34 of 64