Page 44 - QA and QC

P. 44

GMP Training – Quality Assurance and Quality Control by www.gmpsop.com

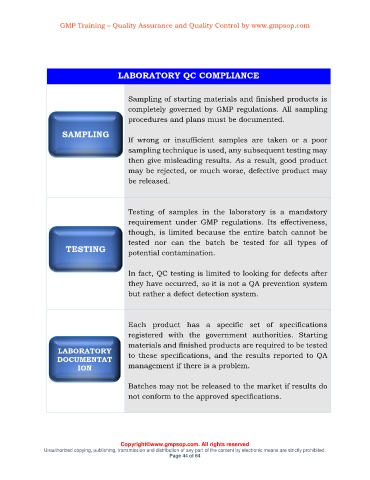

LABORATORY QC COMPLIANCE

Sampling of starting materials and finished products is

completely governed by GMP regulations. All sampling

procedures and plans must be documented.

SAMPLING

If wrong or insufficient samples are taken or a poor

sampling technique is used, any subsequent testing may

then give misleading results. As a result, good product

may be rejected, or much worse, defective product may

be released.

Testing of samples in the laboratory is a mandatory

requirement under GMP regulations. Its effectiveness,

though, is limited because the entire batch cannot be

tested nor can the batch be tested for all types of

TESTING potential contamination.

In fact, QC testing is limited to looking for defects after

they have occurred, so it is not a QA prevention system

but rather a defect detection system.

Each product has a specific set of specifications

registered with the government authorities. Starting

materials and finished products are required to be tested

LABORATORY

DOCUMENTAT to these specifications, and the results reported to QA

ION management if there is a problem.

Batches may not be released to the market if results do

not conform to the approved specifications.

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic means are strictly prohibited.

Page 44 of 64