Page 4 - Industrial Technology Extra - 26th May 2020

P. 4

TORQUE LIMITERS...

Reliable cutterhead protection

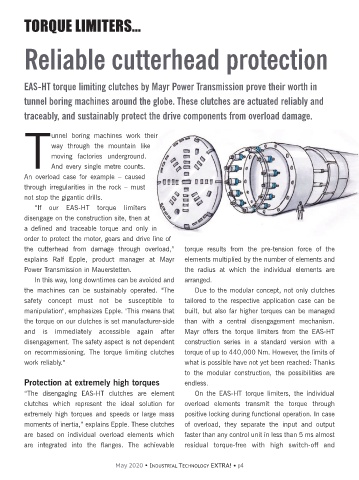

EAS-HT torque limiting clutches by Mayr Power Transmission prove their worth in

tunnel boring machines around the globe. These clutches are actuated reliably and

traceably, and sustainably protect the drive components from overload damage.

unnel boring machines work their

way through the mountain like

moving factories underground.

TAnd every single metre counts.

An overload case for example – caused

through irregularities in the rock – must

not stop the gigantic drills.

“If our EAS-HT torque limiters

disengage on the construction site, then at

a defined and traceable torque and only in

order to protect the motor, gears and drive line of

the cutterhead from damage through overload,” torque results from the pre-tension force of the

explains Ralf Epple, product manager at Mayr elements multiplied by the number of elements and

Power Transmission in Mauerstetten. the radius at which the individual elements are

In this way, long downtimes can be avoided and arranged.

the machines can be sustainably operated. "The Due to the modular concept, not only clutches

safety concept must not be susceptible to tailored to the respective application case can be

manipulation", emphasizes Epple. "This means that built, but also far higher torques can be managed

the torque on our clutches is set manufacturer-side than with a central disengagement mechanism.

and is immediately accessible again after Mayr offers the torque limiters from the EAS-HT

disengagement. The safety aspect is not dependent construction series in a standard version with a

on recommissioning. The torque limiting clutches torque of up to 440,000 Nm. However, the limits of

work reliably." what is possible have not yet been reached: Thanks

to the modular construction, the possibilities are

Protection at extremely high torques endless.

“The disengaging EAS-HT clutches are element On the EAS-HT torque limiters, the individual

clutches which represent the ideal solution for overload elements transmit the torque through

extremely high torques and speeds or large mass positive locking during functional operation. In case

moments of inertia,” explains Epple. These clutches of overload, they separate the input and output

are based on individual overload elements which faster than any control unit in less than 5 ms almost

are integrated into the flanges. The achievable residual torque-free with high switch-off and

May 2020 • INDUSTRIAL TECHNOLOGY EXTRA! • p4