Page 29 - Industrial Technology July 2021

P. 29

MACHINE BUILDING

Efficiency isn’t intuitive

WE ASKED THE EXPERTS AT DANFOSS DRIVES FOR THEIR ADVICE ON SAVING ENERGY WITH FANS

ew would deny the importance of energy

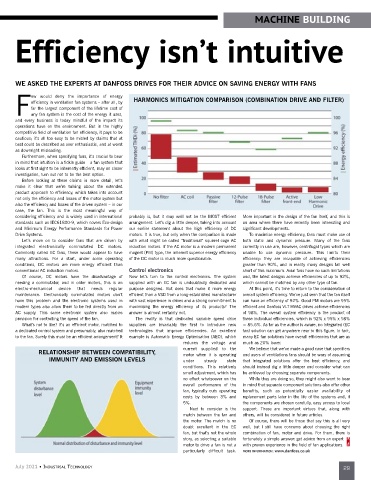

efficiency in ventilation fan systems – after all, by HARMONICS MITIGATION COMPARISON (COMBINATION DRIVE AND FILTER)

far the largest component of the lifetime cost of

Fany fan system is the cost of the energy it uses,

and every business is today mindful of the impact its

operations have on the environment. But in the highly

competitive field of ventilation fan efficiency, it pays to be

cautious; it’s all too easy to be misled by claims that at

best could be described as over enthusiastic, and at worst

as downright misleading.

Furthermore, when specifying fans, it’s crucial to bear

in mind that intuition is a fickle guide – a fan system that

looks at first sight to be inherently efficient, may on closer

investigation, turn out not to be the best option.

Before looking at these claims in more detail, let’s

make it clear that we’re talking about the extended

product approach to efficiency, which takes into account

not only the efficiency and losses of the motor system but

also the efficiency and losses of the driven system – in our

case, the fan. This is the most meaningful way of

considering efficiency and is widely used in international probably is, but it may well not be the MOST efficient More important is the design of the fan itself, and this is

standards such as IEC61800-9, which covers Eco-design arrangement. Let’s dig a little deeper, taking into account an area where there have recently been interesting and

and Minimum Energy Performance Standards for Power our earlier statement about the high efficiency of DC significant developments.

Drive Systems. motors. It is true, but only when the comparison is made To maximise energy efficiency, fans must make use of

Let’s move on to consider fans that are driven by with what might be called “traditional” squirrel cage AC both static and dynamic pressure. Many of the fans

integrated electronically commutated DC motors. induction motors. If the AC motor is a modern permanent currently in use are, however, centrifugal types which are

Commonly called EC fans, these would appear to have magnet (PM) type, the inherent superior energy efficiency unable to use dynamic pressure. This limits their

many attractions. For a start, under some operating of the DC motor is much more questionable. efficiency: they are incapable of achieving efficiencies

conditions, DC motors are more energy efficient than greater than 90%, and in reality many designs fall well

conventional AC induction motors. Control electronics short of this maximum. Axial fans have no such limitations

Of course, DC motors have the disadvantage of Now let’s turn to the control electronics. The system and, the latest designs achieve efficiencies of up to 92%,

needing a commutator, and in older motors, this is an supplied with an EC fan is undoubtedly dedicated and which cannot be matched by any other type of fan.

electro-mechanical device that needs regular purpose designed. But does that make it more energy At this point, it’s time to return to the consideration of

maintenance. Electronically commutated motors don’t efficient than a VSD from a long-established manufacturer overall system efficiency. We’ve just seen that the fan itself

have this problem and the electronic systems used in with vast experience in drives and a strong commitment to can have an efficiency of 92%. Good PM motors are 95%

modern types also allow them to be fed directly from an maximising the energy efficiency of its products? The efficient and Danfoss VLT HVAC drives achieve efficiencies

AC supply. This same electronic system also makes answer is almost certainly not. of 98%. The overall system efficiency is the product of

provision for controlling the speed of the fan. The reality is that dedicated variable speed drive these individual efficiencies, which is 92% x 95% x 98%

What’s not to like? It’s an efficient motor, matched to suppliers are invariably the first to introduce new = 85.6%. As far as the author is aware, no integrated (EC

a dedicated control system and presumably, also matched technologies that improve efficiencies. An excellent fan) solution can get anywhere near to this figure. In fact,

to the fan. Surely this must be an efficient arrangement? It example is Automatic Energy Optimisation (AEO), which many EC fan solutions have overall efficiencies that are as

reduces the voltage and much as 20% lower.

current supplied to the We believe that we’ve made a good case that specifiers

RELATIONSHIP BETWEEN COMPATIBILITY, motor when it is operating and users of ventilations fans should be wary of assuming

IMMUNITY AND EMISSION LEVELS under steady state that integrated solutions offer the best efficiency, and

conditions. This relatively should instead dig a little deeper and consider what can

small adjustment, which has be achieved by choosing separate components.

no effect whatsoever on the While they are doing so, they might also want to bear

overall performance of the in mind that separate component solutions also offer other

fan, typically cuts operating benefits, such as potentially easier availability of

costs by between 3% and replacement parts later in the life of the systems and, if

5%. the components are chosen carefully, easy access to local

Next to consider is the support. These are important virtues that, along with

match between the fan and others, will be considered in future articles.

the motor. The match is no Of course, there will be those that say this is all very

doubt excellent in the EC well, but I still have concerns about choosing the right

fan, but that’s not the whole combination of fan, motor and drive. For them, there is

story, as selecting a suitable fortunately a simple answer: get advice from an expert

motor to drive a fan is not a with proven experience in the field of fan applications.

particularly difficult task. MORE INFORMATION: www.danfoss.co.uk

July 2021 • INDUSTRIAL TECHNOLOGY 29