Page 3 - PDTrac Tech Overview

P. 3

ON-LINE MONITORING THE EFFICIENT WAY

The Results

Too much data and not enough time

… the typical scenario: you’re responsible for maintaining multiple machines and the condition monitoring systems you have provide lots of data,

but you don’t have the time to evaluate which ones need attention, so what are your options:

• Hire an expert to analyze the data

• Send the data from each condition monitoring system to the supplier for a report

• Use an integrated system that will notify you when there is a problem and then an application to access the data to show the reason for

the alert … such as the PDTrac II

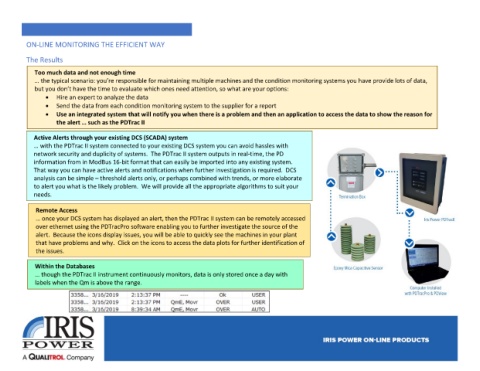

Active Alerts through your existing DCS (SCADA) system

… with the PDTrac II system connected to your existing DCS system you can avoid hassles with

network security and duplicity of systems. The PDTrac II system outputs in real-time, the PD

information from in ModBus 16-bit format that can easily be imported into any existing system.

That way you can have active alerts and notifications when further investigation is required. DCS

analysis can be simple – threshold alerts only, or perhaps combined with trends, or more elaborate

to alert you what is the likely problem. We will provide all the appropriate algorithms to suit your

needs.

Remote Access

… once your DCS system has displayed an alert, then the PDTrac II system can be remotely accessed

over ethernet using the PDTracPro software enabling you to further investigate the source of the

alert. Because the icons display issues, you will be able to quickly see the machines in your plant

that have problems and why. Click on the icons to access the data plots for further identification of

the issues.

Within the Databases

… though the PDTrac II instrument continuously monitors, data is only stored once a day with

labels when the Qm is above the range.