Page 16 - 3-5kV Induction Motor

P. 16

Iris Power MDSP3

BENEFITS: SPECIFICATIONS:

Advanced Algorithms: Iris Power Motor HP: 50hp (37.5kW) & up WHY ANALYZE CAGE

MDSP3 is developed by combining Signal/Noise ratio: >100 dB WINDING FAULTS AND AIR

advanced current signature analysis GAP ECCENTRICITY?

algorithms to accurately predict the Sampling rate: >6500/sec Rotor Core damage: Broken bars

operating slip from the measured Load Current between 35% and 110% cause local temperature increases

current. The slip calculations can also of nameplate and at least 20% of and arcing leading to rotor core

be done at different loads. nominal sensors current damage.

Simplicity: Iris Power MDSP3 can Maximum Rotor Slot Passing

detect cage winding faults and Frequency: 3000Hz Premature degradation of

eccentricity with the use of a single Minimum Full Slip: 0.8% bearings: Broken rotor bars cause

clamp-on current sensor connected torque and speed oscillations on the

to the secondary side of 50 or 60 Hz Dimensions: 6.5” x 3.75” x 1.25” rotor. This degrades the bearings.

motor current transformer; or around (16.51cm x 9.52cm x 3.175cm) Rotor bar movement and failure:

one of the phase leads. Mass: 1 lb (4 kg) Broken rotor bars can lift out of the

Reliability: In line with other Iris KIT CONTENTS: rotor slot due to centrifugal force

Power instruments, the Iris Power or pieces of them can break off and

MDSP3 is designed to significantly • Iris Power MDSP3 processor with 2m cause a stator winding failure.

reduce the risk of false indications silicon rubber current probe cable Rotor bending: Large air pockets

by distinguishing between noise and • Current sensors: 2 included; 5A, and in rotor windings cause non‐uniform

legitimate rotor bar problems, with a combined 250A, 500A and 1000A; bar expansion leading to rotor

noise floor greater than 100 dB. clamp‐on type, 690 V bending and unbalance.

On‐line measurements: All testing is • Digital tachometer Rotor eccentricity: For the rotor

done on‐line, in less than 75 seconds • DAU USB cable rotating off‐center, both static and

in normal mode, to find problems dynamic eccentricity in conjunction

before they cause additional motor • Universal power supply— with the resulting unbalanced

damage. 120/240 V, 50/60 Hz magnetic pull can lead to: 1)

Range and accuracy: Iris Power • MDSP3Pro software bundle for high vibration levels from rotor

MDSP3 can accurately test motors computers running Windows 7 or unbalance, 2) a rotor to rub against

under varying load conditions higher the stator bore which can cause a

where many other test systems give • Quick start guide stator winding failure.

ambiguous results. The Iris Power • Carrying case (IP67, NEMA 4X) Although these problems may

MDSP3 includes two current probes not cause immediate failure, they

to cover a wider range of current OPTIONAL DAU: often lead to deterioration that

from 5A to 1000A. Rugged data acquisition unit with is expensive to repair or may be

Portable and safe: Iris Power Windows operating system and catastrophic. Thus early detection

MDSP3 needs only one input from preinstalled software for Iris Power using the Iris Power MDSP3 prevents

a current probe clamped directly MDSP3 (Panasonic Toughbook or unexpected motor failures.

to one of the phase leads or the similar.

secondary side of a CT at the motor

MCC or breaker. The Iris Power

MDSP3 processor is powered

through the USB connection or

100 to 200 V 50/60 Hz power supply.

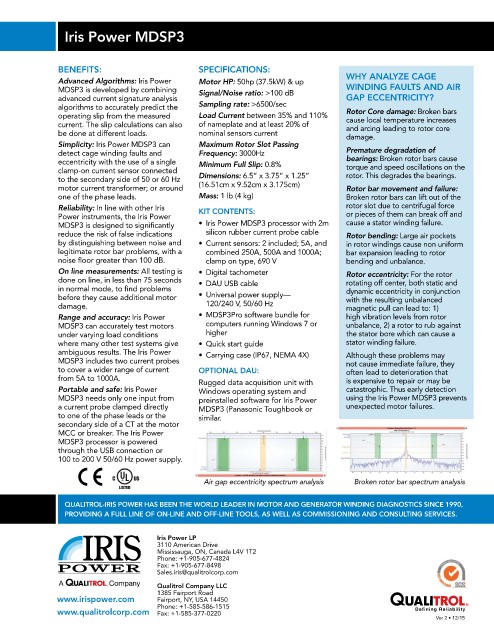

Air gap eccentricity spectrum analysis Broken rotor bar spectrum analysis

QUALITROL-IRIS POWER HAS BEEN THE WORLD LEADER IN MOTOR AND GENERATOR WINDING DIAGNOSTICS SINCE 1990,

PROVIDING A FULL LINE OF ON-LINE AND OFF-LINE TOOLS, AS WELL AS COMMISSIONING AND CONSULTING SERVICES.

Iris Power LP

3110 American Drive

Mississauga, ON, Canada L4V 1T2

Phone: +1-905-677-4824

Fax: +1-905-677-8498

Sales.iris@qualitrolcorp.com

Qualitrol Company LLC

1385 Fairport Road

www.irispower.com Fairport, NY, USA 14450

Phone: +1-585-586-1515

www.qualitrolcorp.com Fax: +1-585-377-0220

Ver 2 • 12/15