Page 9 - Towards better compaction v0.5

P. 9

Towards Better Compaction

Loading

Theory

We need to maximise the number of woodchips in each hold and minimise air gaps as these take-up

space that could be used to store more chips. We also need to apply this consistently across similar

vessels and cargos.

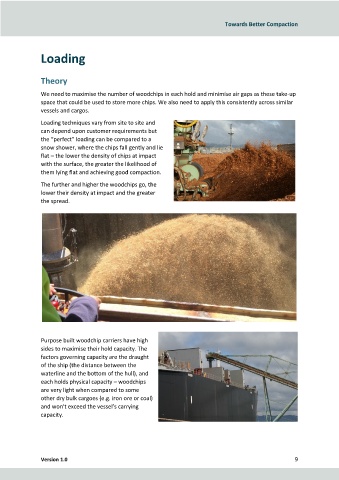

Loading techniques vary from site to site and

can depend upon customer requirements but

the “perfect” loading can be compared to a

snow shower, where the chips fall gently and lie

flat – the lower the density of chips at impact

with the surface, the greater the likelihood of

them lying flat and achieving good compaction.

The further and higher the woodchips go, the

lower their density at impact and the greater

the spread.

Purpose built woodchip carriers have high

sides to maximise their hold capacity. The

factors governing capacity are the draught

of the ship (the distance between the

waterline and the bottom of the hull), and

each holds physical capacity – woodchips

are very light when compared to some

other dry bulk cargoes (e.g. iron ore or coal)

and won't exceed the vessel’s carrying

capacity.

Version 1.0 9