Page 3 - Test file er

P. 3

International Journal of Environment, Agriculture and Biotechnology (IJEAB) Vol-3, Issue-5, Sept-Oct- 2018

http://dx.doi.org/10.22161/ijeab/3.5.48 ISSN: 2456-1878

To determine fruit to sugar to yeast ratio, the experiment Wine was harvested by siphoning carefully, filtered and

was arranged in a 4 x 3 factorial experiment in Completely clarified, transferred to ageing bottles and allowed to age

Randomized Design (CRD) with level of sugar as Factor A for 3 months.

and different amounts of yeast as factor B. The Wine was packed in clear wine bottles and pasteurized

experimental units were replicated three times in storage for 15 min at 75 C.

o

after single preparation.

Factor A, level of sugar (LS) per kilogram dragon fruit 2.3 Product Evaluation

LS1 = 0.25 kg Soluble solids and alcohol content of dragon fruit wine

LS2 = 0.50 kg samples were determined right after fermentation. Total

LS3 = 0.75 kg soluble solid content was determined using refractometer

o

LS4 = 1.0 kg and expressed in Brix. Total acidity was determined by

Factor B, Amount of Yeast (AY) per kilogram dragon titration method and alcohol content of the distillate was

fruit measured using a hydrometer.

AY1 = 1 tsp Sensory properties of the dragon fruit wine were

AY2 = 2 tsp determined by a trained panel. The wine samples were

AY3 = 3 tsp presented in shot glasses to the panel. Unstructured 5-point

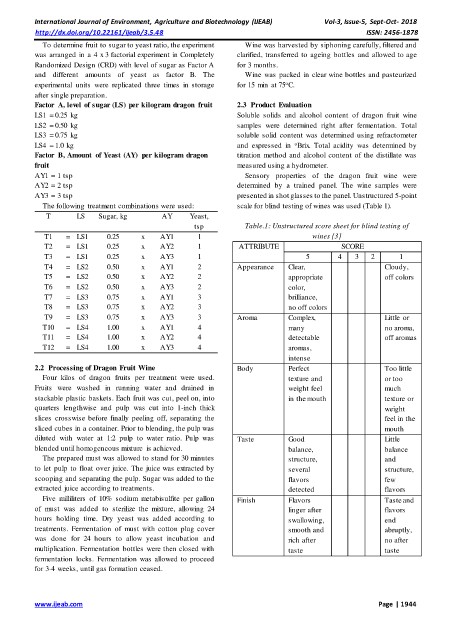

The following treatment combinations were used: scale for blind testing of wines was used (Table 1).

T LS Sugar, kg AY Yeast,

tsp Table.1: Unstructured score sheet for blind testing of

T1 = LS1 0.25 x AY1 1 wines [3]

T2 = LS1 0.25 x AY2 1 ATTRIBUTE SCORE

T3 = LS1 0.25 x AY3 1 5 4 3 2 1

T4 = LS2 0.50 x AY1 2 Appearance Clear, Cloudy,

T5 = LS2 0.50 x AY2 2 appropriate off colors

T6 = LS2 0.50 x AY3 2 color,

T7 = LS3 0.75 x AY1 3 brilliance,

T8 = LS3 0.75 x AY2 3 no off colors

T9 = LS3 0.75 x AY3 3 Aroma Complex, Little or

T10 = LS4 1.00 x AY1 4 many no aroma,

T11 = LS4 1.00 x AY2 4 detectable off aromas

T12 = LS4 1.00 x AY3 4 aromas,

intense

2.2 Processing of Dragon Fruit Wine Body Perfect Too little

Four kilos of dragon fruits per treatment were used. texture and or too

Fruits were washed in running water and drained in weight feel much

stackable plastic baskets. Each fruit was cut, peel on, into in the mouth texture or

quarters lengthwise and pulp was cut into 1-inch thick weight

slices crosswise before finally peeling off, separating the feel in the

sliced cubes in a container. Prior to blending, the pulp was mouth

diluted with water at 1:2 pulp to water ratio. Pulp was Taste Good Little

blended until homogeneous mixture is achieved. balance, balance

The prepared must was allowed to stand for 30 minutes structure, and

to let pulp to float over juice. The juice was extracted by several structure,

scooping and separating the pulp. Sugar was added to the flavors few

extracted juice according to treatments. detected flavors

Five milliliters of 10% sodium metabisulfite per gallon Finish Flavors Taste and

of must was added to sterilize the mixture, allowing 24 linger after flavors

hours holding time. Dry yeast was added according to swallowing, end

treatments. Fermentation of must with cotton plug cover smooth and abruptly,

was done for 24 hours to allow yeast incubation and rich after no after

multiplication. Fermentation bottles were then closed with taste taste

fermentation locks. Fermentation was allowed to proceed

for 3-4 weeks, until gas formation ceased.

www.ijeab.com Page | 1944