Page 4 - Test file er

P. 4

International Journal of Environment, Agriculture and Biotechnology (IJEAB) Vol-3, Issue-5, Sept-Oct- 2018

http://dx.doi.org/10.22161/ijeab/3.5.48 ISSN: 2456-1878

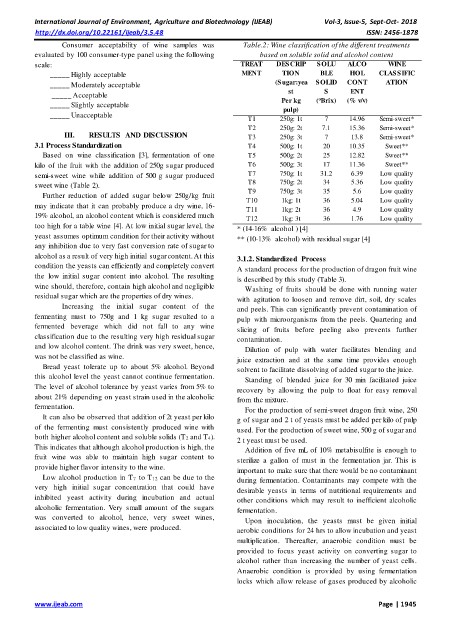

Consumer acceptability of wine samples was Table.2: Wine classification of the different treatments

evaluated by 100 consumer-type panel using the following based on soluble solid and alcohol content

scale: TREAT DESCRIP SOLU ALCO WINE

_____ Highly acceptable MENT TION BLE HOL CLASSIFIC

_____ Moderately acceptable (Sugar:yea SOLID CONT ATION

_____ Acceptable st o S ENT

_____ Slightly acceptable Per kg ( Brix) (% v/v)

pulp)

_____ Unacceptable T1 250g: 1t 7 14.96 Semi-sweet*

T2 250g: 2t 7.1 15.36 Semi-sweet*

III. RESULTS AND DISCUSSION T3 250g: 3t 7 13.8 Semi-sweet*

3.1 Process Standardization T4 500g: 1t 20 10.35 Sweet**

Based on wine classification [3], fermentation of one T5 500g: 2t 25 12.82 Sweet**

kilo of the fruit with the addition of 250g sugar produced T6 500g: 3t 17 11.36 Sweet**

semi-sweet wine while addition of 500 g sugar produced T7 750g: 1t 31.2 6.39 Low quality

sweet wine (Table 2). T8 750g: 2t 34 5.36 Low quality

5.6

T9

Further reduction of added sugar below 250g/kg fruit T10 750g: 3t 35 5.04 Low quality

36

Low quality

1kg: 1t

may indicate that it can probably produce a dry wine, 16- T11 1kg: 2t 36 4.9 Low quality

19% alcohol, an alcohol content which is considered much T12 1kg: 3t 36 1.76 Low quality

too high for a table wine [4]. At low initial sugar level, the * (14-16% alcohol ) [4]

yeast assumes optimum condition for their activity without ** (10-13% alcohol) with residual sugar [4]

any inhibition due to very fast conversion rate of sugar to

alcohol as a result of very high initial sugar content. At this 3.1.2. Standardized Process

condition the yeasts can efficiently and completely convert A standard process for the production of dragon fruit wine

the low initial sugar content into alcohol. The resulting is described by this study (Table 3).

wine should, therefore, contain high alcohol and negligible Washing of fruits should be done with running water

residual sugar which are the properties of dry wines. with agitation to loosen and remove dirt, soil, dry scales

Increasing the initial sugar content of the and peels. This can significantly prevent contamination of

fermenting must to 750g and 1 kg sugar resulted to a pulp with microorganisms from the peels. Quartering and

fermented beverage which did not fall to any wine slicing of fruits before peeling also prevents further

classification due to the resulting very high residual sugar contamination.

and low alcohol content. The drink was very sweet, hence, Dilution of pulp with water facilitates blending and

was not be classified as wine. juice extraction and at the same time provides enough

Bread yeast tolerate up to about 5% alcohol. Beyond solvent to facilitate dissolving of added sugar to the juice.

this alcohol level the yeast cannot continue fermentation. Standing of blended juice for 30 min facilitated juice

The level of alcohol tolerance by yeast varies from 5% to recovery by allowing the pulp to float for easy removal

about 21% depending on yeast strain used in the alcoholic from the mixture.

fermentation. For the production of semi-sweet dragon fruit wine, 250

It can also be observed that addition of 2t yeast per kilo g of sugar and 2 t of yeasts must be added per kilo of pulp

of the fermenting must consistently produced wine with used. For the production of sweet wine, 500 g of sugar and

both higher alcohol content and soluble solids (T2 and T4). 2 t yeast must be used.

This indicates that although alcohol production is high, the Addition of five mL of 10% metabisulfite is enough to

fruit wine was able to maintain high sugar content to sterilize a gallon of must in the fermentation jar. This is

provide higher flavor intensity to the wine. important to make sure that there would be no contaminant

Low alcohol production in T7 to T12 can be due to the during fermentation. Contaminants may compete with the

very high initial sugar concentration that could have desirable yeasts in terms of nutritional requirements and

inhibited yeast activity during incubation and actual other conditions which may result to inefficient alcoholic

alcoholic fermentation. Very small amount of the sugars fermentation.

was converted to alcohol, hence, very sweet wines, Upon inoculation, the yeasts must be given initial

associated to low quality wines, were produced. aerobic conditions for 24 hrs to allow incubation and yeast

multiplication. Thereafter, anaerobic condition must be

provided to focus yeast activity on converting sugar to

alcohol rather than increasing the number of yeast cells.

Anaerobic condition is provided by using fermentation

locks which allow release of gases produced by alcoholic

www.ijeab.com Page | 1945