Page 7 - Concrete-Technology-Interacted_Book_Prof-MIK_Neat

P. 7

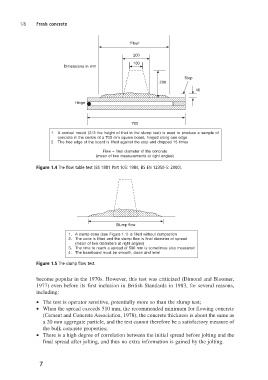

1/8 Fresh concrete ‘Flow’

Dimensions in mm 200

Hinge 130

Stop

200

40

700

1. A conical mould (2/ 3 the height of that in the slump test) is used to produce a sample of

concrete in the centre of a 700 mm square board, hinged along one edge

2. The free edge of the board is lifted against the stop and dropped 15 times

Flow = final diameter of the concrete

(mean of two measurements at right angles)

Figure 1.4 The flow table test (BS 1881 Part 105: 1984, BS EN 12350-5: 2000).

Slump flow

1. A slump cone (see Figure 1.1) is filled without compaction

2. The cone is lifted and the slump flow is final diameter of spread

(mean of two diameters at right angles)

3. The time to reach a spread of 500 mm is sometimes also measured

4. The baseboard must be smooth, clean and level

Figure 1.5 The slump flow test.

become popular in the 1970s. However, this test was criticized (Dimond and Bloomer,

1977) even before its first inclusion in British Standards in 1983, for several reasons,

including:

• The test is operator sensitive, potentially more so than the slump test;

• When the spread exceeds 510 mm, the recommended minimum for flowing concrete

(Cement and Concrete Association, 1978), the concrete thickness is about the same as

a 20 mm aggregate particle, and the test cannot therefore be a satisfactory measure of

the bulk concrete properties;

• There is a high degree of correlation between the initial spread before jolting and the

final spread after jolting, and thus no extra information is gained by the jolting.

7