Page 52 - Green Builder Magazine Nov-Dec 2017 Issue

P. 52

Active Plastic Lumber

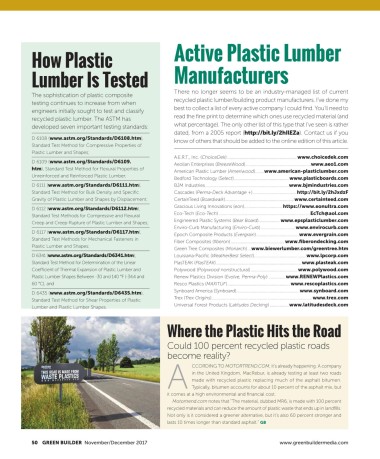

How Plastic

Lumber Is Tested Manufacturers

There no longer seems to be an industry-managed list of current

The sophistication of plastic composite

testing continues to increase from when recycled plastic lumber/building product manufacturers. I’ve done my

engineers initially sought to test and classify best to collect a list of every active company I could find. You’ll need to

recycled plastic lumber. The ASTM has read the fine print to determine which ones use recycled material (and

developed seven important testing standards: what percentage). The only other list of this type that I’ve seen is rather

dated, from a 2005 report (http://bit.ly/2hIlEZa). Contact us if you

D 6108 (www.astm.org/Standards/D6108.htm), know of others that should be added to the online edition of this article.

Standard Test Method for Compressive Properties of

Plastic Lumber and Shapes;

A.E.R.T., Inc. (ChoiceDek) .............................................................. www.choicedek.com

D 6109 (www.astm.org/Standards/D6109. Aeolian Enterprises (BreezeWood)...........................................................www.aeo1.com

htm), Standard Test Method for Flexural Properties of American Plastic Lumber (Ameriwood) ........www.american-plasticlumber.com

Unreinforced and Reinforced Plastic Lumber;

Bedford Technology (Select) ................................................. www.plasticboards.com

D 6111 (www.astm.org/Standards/D6111.htm), BJM Industries ...........................................................................www.bjmindustries.com

Standard Test Method for Bulk Density and Specific Cascades (Perma-Deck Advantage +) .......................................http://bit.ly/2hJxdzF

Gravity of Plastic Lumber and Shapes by Displacement; CertainTeed (Boardwalk) ..............................................................www.certainteed.com

D 6112 (www.astm.org/Standards/D6112.htm), Gracious Living Innovations (eon).................................. https://www.eonultra.com

Standard Test Methods for Compressive and Flexural Eco-Tech (Eco-Tech) ..................................................................................EcTch@aol.com

Creep and Creep-Rupture of Plastic Lumber and Shapes; Engineered Plastic Systems (Bear Board) ................... www.epsplasticlumber.com

Enviro-Curb Manufacturing (Enviro-Curb) ...............................www.envirocurb.com

D 6117 (www.astm.org/Standards/D6117.htm), Epoch Composite Products (Evergrain) ......................................www.evergrain.com

Standard Test Methods for Mechanical Fasteners in Fiber Composites (fiberon) ................................................ www.fiberondecking.com

Plastic Lumber and Shapes;

Green Tree Composites (Monarch) ...www.biewerlumber.com/greentree.htm

D 6341 (www.astm.org/Standards/D6341.htm), Louisiana-Pacific (WeatherBest Select) ...............................................www.lpcorp.com

Standard Test Method for Determination of the Linear PlasTEAK (PlasTEAK) ............................................................................ www.plasteak.com

Coefficient of Thermal Expansion of Plastic Lumber and Polywood (Polywood nonstructural) ..........................................www.polywood.com

Plastic Lumber Shapes Between -30 and 140 °F (-34.4 and Renew Plastics Division (Evolve, Perma-Poly) ...............www.RENEWPlastics.com

60 °C); and Resco Plastics (MAXITUF) ........................................................ www.rescoplastics.com

D 6435 (www.astm.org/Standards/D6435.htm), Synboard America (Synboard) .........................................................www.synboard.com

Standard Test Method for Shear Properties of Plastic Trex (Trex Origins) ..........................................................................................www.trex.com

Lumber and Plastic Lumber Shapes. Universal Forest Products (Latitudes Decking) .................www.latitudesdeck.com

Where the Plastic Hits the Road

Could 100 percent recycled plastic roads

become reality?

CCORDING TO MOTORTREND.COM, it’s already happening. A company

in the United Kingdom, MacRebur, is already testing at least two roads

made with recycled plastic replacing much of the asphalt bitumen.

A Typically, bitumen accounts for about 10 percent of the asphalt mix, but

it comes at a high environmental and financial cost.

Motortrend.com notes that “The material, dubbed MR6, is made with 100 percent

recycled materials and can reduce the amount of plastic waste that ends up in landfills.

Not only is it considered a greener alternative, but it’s also 60 percent stronger and

lasts 10 times longer than standard asphalt.” GB

50 GREEN BUILDER November/December 2017 www.greenbuildermedia.com

44-51 GB 1117 Perils of Plastic.indd 50 11/17/17 11:32 AM