Page 53 - Green Builder Magazine Nov-Dec 2017 Issue

P. 53

3D Printing: The Next Frontier

for Recycled Plastics

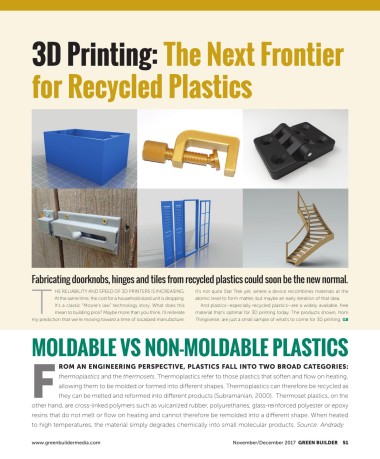

Fabricating doorknobs, hinges and tiles from recycled plastics could soon be the new normal.

HE RELIABILITY AND SPEED OF 3D PRINTERS IS INCREASING. It’s not quite Star Trek yet, where a device recombines materials at the

At the same time, the cost for a household-sized unit is dropping. atomic level to form matter, but maybe an early iteration of that idea.

It’s a classic “Moore’s law” technology story. What does this And plastics—especially recycled plastics—are a widely available, free

T mean to building pros? Maybe more than you think. I’ll reiterate material that’s optimal for 3D printing today. The products shown, from

my prediction that we’re moving toward a time of localized manufacture. Thingiverse, are just a small sample of what’s to come for 3D printing. GB

MOLDABLE VS NON-MOLDABLE PLASTICS

ROM AN ENGINEERING PERSPECTIVE, PLASTICS FALL INTO TWO BROAD CATEGORIES:

thermoplastics and the thermosets. Thermoplastics refer to those plastics that soften and flow on heating,

allowing them to be molded or formed into different shapes. Thermoplastics can therefore be recycled as

F they can be melted and reformed into different products (Subramanian, 2000). Thermoset plastics, on the

other hand, are cross-linked polymers such as vulcanized rubber, polyurethanes, glass-reinforced polyester or epoxy

resins that do not melt or flow on heating and cannot therefore be remolded into a different shape. When heated

to high temperatures, the material simply degrades chemically into small molecular products. Source: Andrady

www.greenbuildermedia.com November/December 2017 GREEN BUILDER 51

44-51 GB 1117 Perils of Plastic.indd 51 11/17/17 11:32 AM