Page 1005 - Master Catalog 2017, Inch

P. 1005

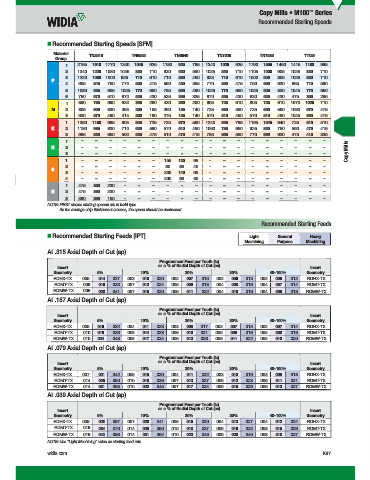

Copy Mills • M100 Series

™

Recommended Starting Speeds

Recommended Starting Speeds [SFM]

Material TN2510 TN6525 TN6540 TN7525 TN7535 TTI25

Group

1 2165 1910 1770 1340 1045 925 1180 925 785 1340 1025 925 1790 1555 1460 1415 1180 985

2 1340 1220 1080 1045 830 710 830 630 550 1025 830 710 1105 1000 905 1025 830 710

3 1220 1080 1000 925 710 610 710 550 450 925 710 610 1000 905 805 1025 830 710

P

4 905 845 750 770 550 475 590 430 355 770 550 475 750 690 630 865 710 590

5 1080 985 905 1025 770 650 785 590 490 1025 770 650 1025 905 830 1045 770 650

6 750 670 570 670 535 430 535 395 335 670 535 430 630 535 430 475 355 295

1 890 785 690 630 395 260 430 260 200 805 725 610 805 725 610 1570 1025 710

M 2 805 690 630 395 260 155 260 155 140 725 630 550 725 630 550 1060 670 475

3 630 570 490 415 260 180 275 155 140 570 510 450 570 510 450 1045 690 475

1 1380 1180 985 905 805 725 725 670 590 1240 925 785 1165 1045 940 725 610 510

K 2 1180 985 830 710 630 590 570 510 450 1060 785 650 925 830 750 590 475 415

3 985 830 650 590 535 475 510 475 415 785 650 550 770 690 630 475 415 335

1 – – – – – – – – – – – – – – – – – –

N 2 – – – – – – – – – – – – – – – – – –

3 – – – – – – – – – – – – – – – – – – Copy Mills

1 – – – – – – 155 120 95 – – – – – – – – –

2 – – – – – – 80 60 40 – – – – – – – – –

S

3 – – – – – – 235 140 95 – – – – – – – – –

4 – – – – – – 200 95 80 – – – – – – – – –

1 475 360 230 – – – – – – – – – – – – – – –

H 2 475 360 230 – – – – – – – – – – – – – – –

3 380 260 150 – – – – – – – – – – – – – – –

NOTE: FIRST choice starting speeds are in bold type.

As the average chip thickness increases, the speed should be decreased.

Recommended Starting Feeds

Recommended Starting Feeds [IPT] Light General Heavy

Machining Purpose Machining

At .315 Axial Depth of Cut (ap)

Programmed Feed per Tooth (fz)

as a % of Radial Depth of Cut (ae)

Insert Insert

Geometry 5% 10% 20% 30% 40–100% Geometry

RDHX-TX .005 .014 .027 .003 .010 .020 .002 .007 .015 .002 .006 .013 .002 .006 .012 RDHX-TX

RDMT-TX .009 .016 .033 .007 .012 .024 .005 .009 .018 .004 .008 .016 .004 .007 .014 RDMT-TX

RDMW-TX .009 .020 .041 .007 .015 .030 .005 .011 .022 .004 .010 .019 .004 .009 .018 RDMW-TX

At .157 Axial Depth of Cut (ap)

Programmed Feed per Tooth (fz)

Insert as a % of Radial Depth of Cut (ae) Insert

Geometry 5% 10% 20% 30% 40–100% Geometry

RDHX-TX .005 .016 .032 .004 .011 .023 .003 .008 .017 .002 .007 .015 .002 .007 .014 RDHX-TX

RDMT-TX .010 .019 .038 .008 .014 .028 .006 .010 .021 .005 .009 .018 .005 .008 .016 RDMT-TX

RDMW-TX .010 .024 .048 .008 .017 .034 .006 .013 .026 .005 .011 .022 .005 .010 .020 RDMW-TX

At .079 Axial Depth of Cut (ap)

Programmed Feed per Tooth (fz)

as a % of Radial Depth of Cut (ae)

Insert Insert

Geometry 5% 10% 20% 30% 40–100% Geometry

RDHX-TX .007 .021 .042 .005 .015 .030 .004 .011 .022 .003 .010 .019 .003 .009 .018 RDHX-TX

RDMT-TX .014 .025 .050 .010 .018 .036 .007 .013 .027 .006 .012 .023 .006 .011 .021 RDMT-TX

RDMW-TX .014 .031 .063 .010 .022 .045 .007 .017 .034 .006 .015 .029 .006 .013 .027 RDMW-TX

At .039 Axial Depth of Cut (ap)

Programmed Feed per Tooth (fz)

as a % of Radial Depth of Cut (ae)

Insert Insert

Geometry 5% 10% 20% 30% 40–100% Geometry

RDHX-TX .009 .028 .057 .007 .020 .041 .005 .015 .030 .004 .013 .027 .004 .012 .024 RDHX-TX

RDMT-TX .019 .034 .070 .014 .025 .050 .010 .018 .037 .009 .016 .032 .008 .015 .029 RDMT-TX

RDMW-TX .019 .043 .088 .014 .031 .062 .010 .023 .046 .009 .020 .040 .008 .018 .037 RDMW-TX

NOTE: Use “Light Machining” value as starting feed rate.

widia.com K97

10/29/15 1:43 PM

WID_Master16_IndexableMIlling_CopyMills_K096_K097_Minch_REBRAND.indd 97 L V i WID M 16 I d bl MIlli C Mill K096 K097 Mi h REBRANDO b 1420151151AM