Page 1038 - Master Catalog 2017, Inch

P. 1038

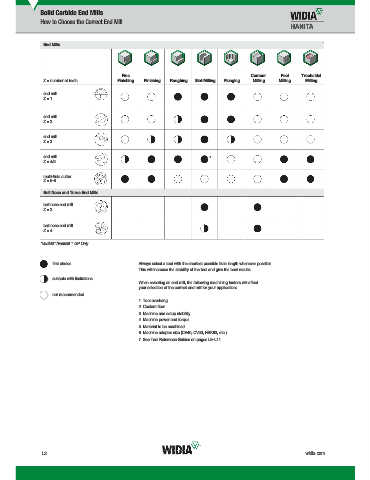

Solid Carbide End Mills

How to Choose the Correct End Mill

End Mills

Fine Contour Peel Trochoidal

Z = number of teeth Finishing Finishing Roughing Slot Milling Plunging Milling Milling Milling

end mill

Z = 1

end mill

Z = 2

end mill

Z = 3

end mill *

Z = 4/5

multi-flute cutter

Z = 6-8

Ball Nose and Torus End Mills

ball nose end mill

Z = 2

ball nose end mill

Z = 4

*VariMill ™ /VariMill ™ GP Only

first choice Always select a tool with the shortest possible flute length whenever possible.

This will increase the stability of the tool and give the best results.

suitable with limitations

When selecting an end mill, the following machining factors will affect

your selection of the correct end mill for your application:

not recommended

1. Tool overhang.

2. Coolant flow.

3. Machine and setup stability.

4. Machine power and torque.

5. Material to be machined.

6. Machine adapter size (CV40, CV50, HSK63, etc.).

7. See Tool Reference Guides on pages L6–L11.

L2 widia.com

L002 L003 MI h REBRANDN

WID M

16 S lidE dMilli

V

i

i

I

S

L WID_Master16_SolidEndMilling_SectionIntro_L002_L003_MInch_REBRAND.indd 2 b 10 20158 54AM 11/11/15 9:35 AM