Page 136 - Master Catalog 2017, Inch

P. 136

™

WIDIA VariTurn

™

High-Temp Alloys • Iron, Cobalt, Nickel-Based and Titanium Alloys

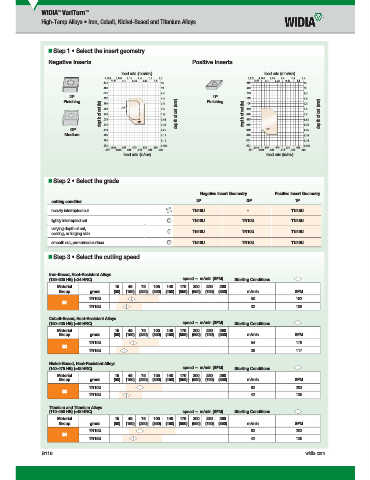

Step 1 • Select the insert geometry

Negative Inserts Positive Inserts

feed rate (mm/rev) feed rate (mm/rev)

2P 1P

Finishing Finishing

depth of cut (in) depth of cut (mm) depth of cut (in) depth of cut (mm)

..GP

Medium

feed rate (in/rev) feed rate (in/rev)

Step 2 • Select the grade

Negative Insert Geometry Positive Insert Geometry

cutting condition 2P ..GP 1P

heavily interrupted cut TN15U – TN15U

lightly interrupted cut TN10U TN10U TN15U

varying depth of cut, TN10U TN10U TN10U

casting, or forging skin

smooth cut, pre-turned surface TN10U TN10U TN10U

Step 3 • Select the cutting speed

Iron-Based, Heat-Resistant Alloys

(135–320 HB) ()34 HRC) speed — m/min (SFM) Starting Conditions

Material 15 45 75 105 140 170 200 230 260

Group grade (50) (150) (250) (350) (450) (550) (650) (750) (850) m/min SFM

TN10U 50 162

S1

TN15U 33 108

Cobalt-Based, Heat-Resistant Alloys

(150–425 HB) ()45 HRC) speed — m/min (SFM) Starting Conditions

Material 15 45 75 105 140 170 200 230 260

Group grade (50) (150) (250) (350) (450) (550) (650) (750) (850) m/min SFM

TN10U 54 176

S2

TN15U 36 117

Nickel-Based, Heat-Resistant Alloys

(140–475 HB) ()48 HRC) speed — m/min (SFM) Starting Conditions

Material 15 45 75 105 140 170 200 230 260

Group grade (50) (150) (250) (350) (450) (550) (650) (750) (850) m/min SFM

TN10U 63 203

S3

TN15U 42 135

Titanium and Titanium Alloys

(110–450 HB) ()48 HRC) speed — m/min (SFM) Starting Conditions

Material 15 45 75 105 140 170 200 230 260

Group grade (50) (150) (250) (350) (450) (550) (650) (750) (850) m/min SFM

TN10U 63 203

S4

TN15U 42 135

B116 widia.com

I

V

B116 B117 Mi

16 T

WID M

i

i

L WID_Master16_Turning_Inserts_B116_B117_Minch_REBRAND.indd 116 h REBRAND N b 9 2015 10 44 AM 11/10/15 11:02 AM