Page 46 - Master Catalog 2017, Inch

P. 46

™

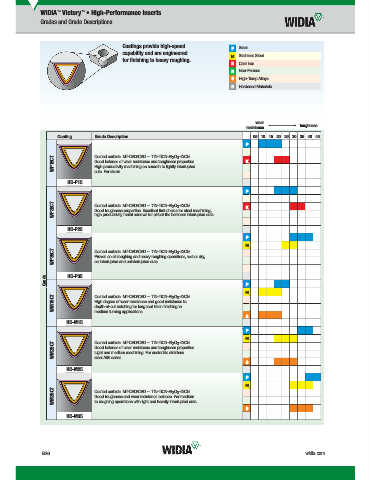

WIDIA Victory • High-Performance Inserts

™

Grades and Grade Descriptions

Coatings provide high-speed

P Steel

capability and are engineered

M Stainless Steel

for finishing to heavy roughing.

K Cast Iron

N Non-Ferrous

S High-Temp Alloys

H Hardened Materials

wear

resistance toughness

Coating Grade Description 05 10 15 20 25 30 35 40 45

P

WP15CT Coated carbide. MT-CVD/CVD — TiN-TiCN-Al O -ZrCN. K

2 3

Good balance of wear resistance and toughness properties.

High productivity machining on smooth to lightly interrupted

cuts. For steels.

HC-P15

P

WP25CT Coated carbide. MT-CVD/CVD — TiN-TiCN-Al O -ZrCN. K

2 3

Good toughness properties. Excellent fi rst choice for steel machining,

high productivity metal removal for all but the harshest interrupted cuts.

HC-P25

P

M

WP35CT Coated carbide. MT-CVD/CVD — TiN-TiCN-Al O -ZrCN.

2 3

Proven on all roughing and heavy roughing operations, wet or dry,

on interrupted and uninterrupted cuts.

Grade HC-P35 P

M

Coated carbide. MT-CVD/CVD — TiN-TiCN-Al O -ZrCN.

WM15CT High degree of wear resistance and good resistance to

2 3

depth-of-cut notching for long tool life in fi nishing to

medium turning applications.

S

HC-M15

P

M

Coated carbide. MT-CVD/CVD — TiN-TiCN-Al O -ZrCN.

WM25CT Good balance of wear resistance and toughness properties.

2 3

Light and medium machining. For austenitic stainless

steel AISI series.

S

HC-M25

P

M

WM35CT Coated carbide. MT-CVD/CVD — TiN-TiCN-Al O -ZrCN.

2 3

Good toughness and wear resistance balance. For medium

to roughing operations with light and heavily interrupted cuts.

S

HC-M35

B26 widia.com

V

B026 B027 Mi

I

i

WID M

i

16 T

L WID_Master16_Turning_Inserts_B026_B027_Minch_REBRAND.indd 26 h REBRAND N b 9 2015 10 37 AM 11/10/15 11:02 AM