Page 47 - Master Catalog 2017, Inch

P. 47

™

WIDIA Victory • High-Performance Inserts

™

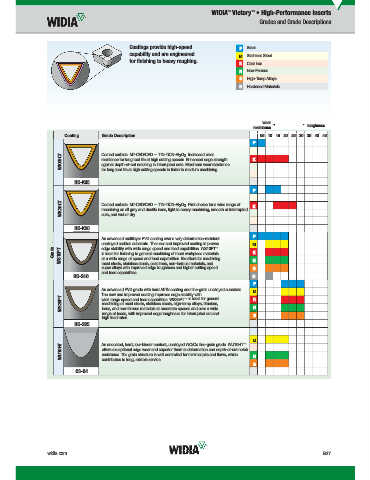

Grades and Grade Descriptions

Coatings provide high-speed

P Steel

capability and are engineered

M Stainless Steel

for finishing to heavy roughing.

K Cast Iron

N Non-Ferrous

S High-Temp Alloys

H Hardened Materials

wear

resistance toughness

Coating Grade Description 05 10 15 20 25 30 35 40 45

P

WK05CT Coated carbide. MT-CVD/CVD — TiN-TiCN-Al O . Increased wear K

2 3

resistance for long tool life at high cutting speeds. Enhanced edge strength

against depth-of-cut notching in interrupted cuts. Maximum wear resistance

for long tool life at high cutting speeds in fi nish to medium machining.

HC-K05

P

WK20CT Coated carbide. MT-CVD/CVD — TiN-TiCN-Al O . First choice for a wide range of K

2 3

machining on all gray and ductile irons, light to heavy machining, smooth or interrupted

cuts, and wet or dry.

HC-K20

P

An advanced multilayer PVD coating over a very deformation-resistant

unalloyed carbide substrate. The new and improved coating improves M

Grade WS10PT edge stability with wide range speed and feed capabilities. WS10PT ™ K

is ideal for fi nishing to general machining of most workpiece materials

at a wide range of speed and feed capabilities. Excellent for machining

most steels, stainless steels, cast irons, non-ferrous materials, and

super alloys with improved edge toughness and higher cutting speed N S

and feed capabilities.

HC-S10 H

P

An advanced PVD grade with hard AlTiN coating and fi ne-grain unalloyed substrate.

The new and improved coating improves edge stability with M

WS25PT wide range speed and feed capabilities. WS25PT ™ is ideal for general K

machining of most steels, stainless steels, high-temp alloys, titanium,

N

irons, and non-ferrous materials at moderate speeds and over a wide

range of feeds, with improved edge toughness for interrupted cut and

high feed rates. S

HC-S25

M

WU10HT offers exceptional edge wear and superior thermal deformation and depth-of-cut notch N

An uncoated, hard, low-binder content, unalloyed WC/Co fi ne-grain grade. WU10HT ™

resistance. The grain structure is well controlled for minimal pits and fl aws, which

contributes to long, reliable service.

S

C3-C4

widia.com B27

11/10/15 11:02 AM

WID_Master16_Turning_Inserts_B026_B027_Minch_REBRAND.indd 27 L V i WID M 16 T i I B026 B027 Mi h REBRANDN b 920151037AM