Page 561 - Master Catalog 2017, Inch

P. 561

TopGroove

™

Custom Order TopGroove Inserts with Chip Control

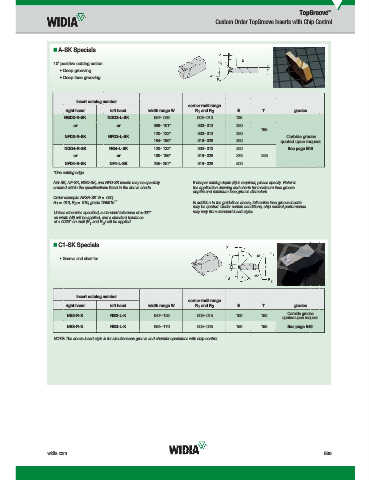

A-SK Specials

10˚ positive cutting action

• Deep grooving

• Deep face grooving

insert catalog number

corner radii range

right hand left hand width range W R and R 2 E T grades

1

NGD3-R-SK NGD3-L-SK .057–.069 .003–.013 .125

or or .089–.101* .003–.013 .250

.195

.120–.132* .003–.013 .250

NFD3-R-SK NFD3-L-SK Carbide grades

.184–.196* .018–.028 .250 quoted upon request.

NGD4-R-SK NG4-L-SK .120–.132* .003–.013 .250 See page E49.

or or .180–.196* .018–.028 .375 .255

NFD4-R-SK NF4-L-SK .245–.257* .018–.028 .500

*One cutting edge.

NG-SK, NF-SK, NGD-SK, and NFD-SK inserts may be specially If deeper cutting depth (E) is required, please specify. Refer to

ordered within the specifi cations listed in the above charts. the application drawing and charts for maximum face groove

depths and minimum face groove diameters.

Order example: NF3R-SK W = .090,

™

R = .010, R = .010, grade TN6010 . In addition to the guidelines above, full radius face groove inserts

2

1

may be quoted. Under certain conditions, chip control performance

Unless otherwise specifi ed, a standard tolerance of ±.001" may vary from standard insert styles.

on width (W) will be applied, and a standard tolerance

of ±.0025" on radii (R and R ) will be applied.

1 2

C1-SK Specials

• Groove and chamfer

insert catalog number

corner radii range

right hand left hand width range W R and R 2 E T grades

1

Carbide grades

NB2-R-K NB2-L-K .047–.125 .005–.015 .100 .150

quoted upon request.

NB3-R-K NB3-L-K .094–.170 .005–.025 .150 .195 See page E49.

NOTE: The above insert style is for simultaneous groove and chamfer operations with chip control.

widia.com E89

WID_Master16_Turning_Grooving&CutOff_E088_E089_Minch_REBRAND.indd 89 L V i WID M 16 T i G i &C Off E088 E089 Mi h REBRANDN b 102015743AM

11/10/15 11:14 AM